Notpla salvages seaweed by-product to make paper

Sustainable packaging brand Notpla has used seaweed leftover from its own production processes to create paper that can be turned into envelopes and boxes.

Notpla introduced its eponymous product Notpla Paper in collaboration with Canopy, a nonprofit organisation that aims to protect forests and animal species threatened by climate change.

Notpla Paper is made from 30 per cent seaweed by-product

Notpla Paper is made from 30 per cent seaweed by-product

According to its creators, Notpla Paper is made from 30 per cent seaweed by-product, which refers to any secondary product that is made as a result of a production process and is often thrown away and wasted.

Notpla – which is a shortening of "not plastic" – uses pure seaweed to create all of its existing products, which include biodegradable condiment sachets and coating for food containers.

The brand explained that it wanted to find a use for the seaweed leftover from its production processes "to make sure nothing is wasted".

The material can be used as packaging

The material can be used as packaging

"Each of our products uses different extracts of seaweed, leaving the fibrous part of it behind," Notpla design director Karlijn Sibbel told Dezeen.

"This by-product represents a significant amount of pure raw seaweed. From our desire to utilise every part of the seaweed, the idea to upcycle this material came naturally."

The paper can create containers for various products

The paper can create containers for various products

Notpla claimed that using one tonne of seaweed by-product could save up to four tonnes of trees being felled, preventing deforestation.

"From a circular mindset in which waste doesn't exist, we aim to reduce the need for virgin materials as much as possible and therefore prefer the use of by-products," said Sibbel.

"With the need for seaweed extracts in our other product lines, we want to make sure every part of the seaweed is fully valued and used to the best extent."

A minimal wine label made from Notpla Paper

A minimal wine label made from Notpla Paper

The brand said that the remaining 70 per cent of Notpla Paper is composed of a mixture of mainly other recycled materials and a small portion of traditional virgin wood pulp.

"Our design process is firstly driven by an environmental point of view," Sibbel continued. "This means that we use as much seaweed as possible, as little virgin wood as possible and no synthetic additives, which are currently the status quo in papermaking."

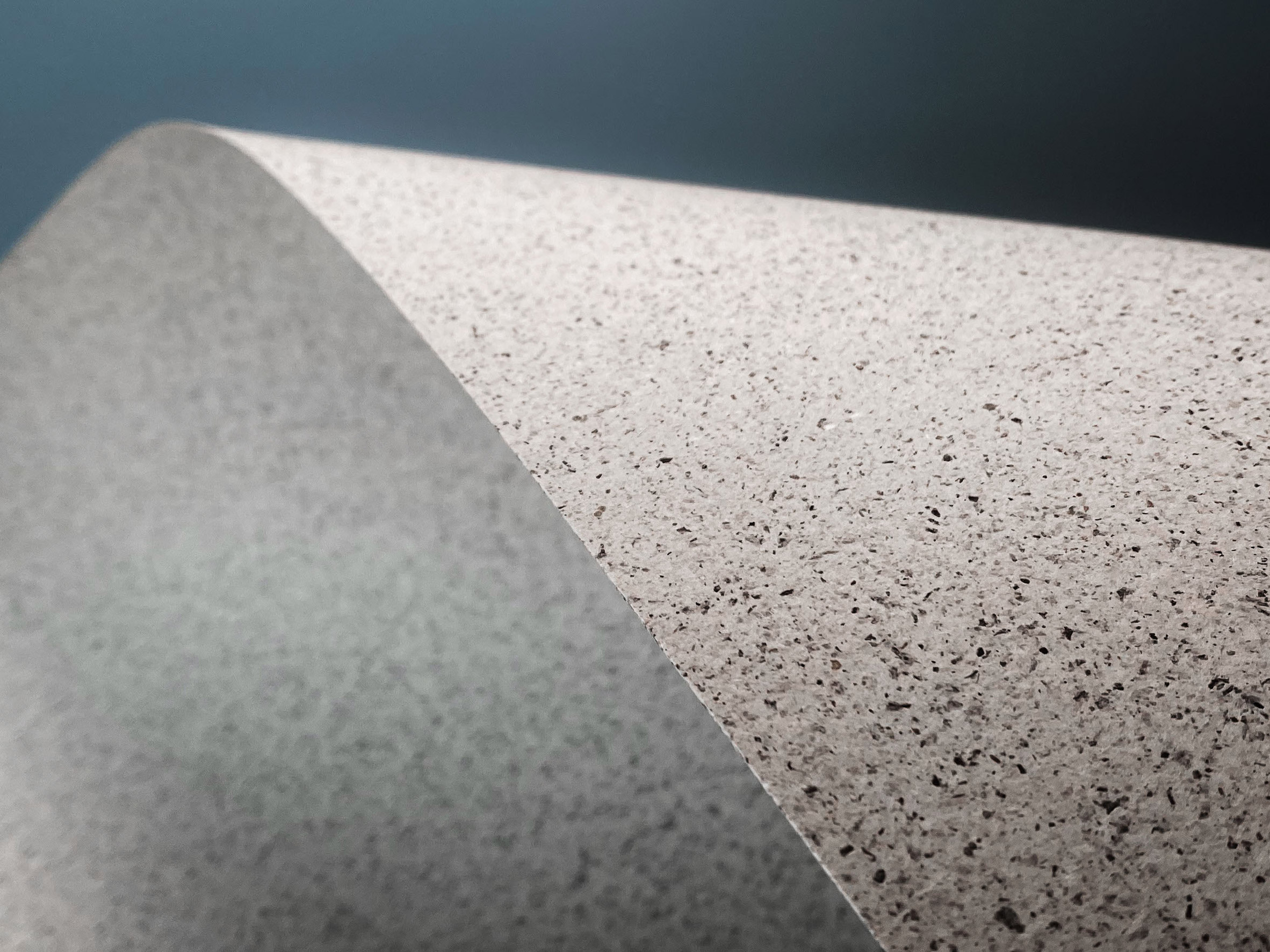

The paper has a speckled appearance

The paper has a speckled appearance

Speckled and neutrally-toned in appearance, Notpla Paper can be used to package products such as hand soap and toothbrushes, as well as to create boxes, envelopes and labels on wine bottles.

Sibbel explained that while the paper currently contains some virgin wood, Notpla aims to create entirely wood-free paper by 2024.

[

Read:

Nienke Hoogvliet launches Zeefier brand to produce natural seaweed dyes for the fashion industry

](https://www.dezeen.com/2021/11/14/zeefier-natural-seaweed-dyes-nienke-hoogvliet/)

While the brand did not specify which materials will be used to achieve this, its intention is to blend alternative fibres with the seaweed by-product to will support the paper's technical properties.

"Our ambition is to alleviate pressure on forests and decrease the environmental impact of paper manufacturing," concluded Sibbel.

Notpla aims to create entirely wood-free paper by 2024

Notpla aims to create entirely wood-free paper by 2024

Notpla Paper is part of Canopy's Pack4Good initiative, a project that is challenging brands to create sustainable alternatives to traditional paper packaging.

Founded in 2014 Rodrigo Garcia Gonzalez and Pierre Paslier while the pair were studying Innovation Design Engineering, Notpla also manufactures biodegradable seaweed packaging, which was shortlisted in the sustainable design category at the 2021 Dezeen Awards.

The images are courtesy of Notpla.

The post Notpla salvages seaweed by-product to make paper appeared first on Dezeen.

#all #design #products #sustainabledesign #paper #packaging #seaweed #circulareconomy #recycling #notpla