#packaging

Seen at Carleton University today, on a sidewalk near some garbage cans. It was about 4 ft X 2 ft (120 cm X 60 cm) and made of foam. Not sure what it was, #art, #packaging material, #acoustic or #radar absorbent tiling or something else entirely?? #WTF

Making the switch from setup.py to pyproject.toml

My experience:

* It's been easy to do the switch

* It's cleaner than using setup.py

* pyproject.toml can also be used for various tool configurations (pylint, pytest, etc)

* One drawback: I used to run a script after pip install using cmdclass in setup.py, and this can still be done, but the problem is that there isn't much possibility to import packages (possibly because the packaging now is done inside a virtual environment, i'm not sure). I cannot even import modules in my own package

#Nanotechnology Used #in Over 2,000 #Food Items Goes Unlabeled Due to Weird FDA Loophole:

Source: https://youtube.com/watch?v=wlAi3KIeTN8

Nanotechnology Used in #Covid #poison darts, 2,000 #Foods Goes #Unlabeled

Extremely small #particles of various #compounds are being used as food #additives, with unknown effects

If you’re one of those people that can often be found in the food aisles of grocery stores reading labels and looking for ingredients you can’t pronounce and don’t want to eat, you’ve most likely noticed several ingredients that, unbeknownst to you, are made using nanotechnology—a process that converts silver, copper, gold, aluminum, silicon, carbon, and metal oxides, among other metals, into atom-sized particles that are one-billionth of a meter in size.

Commonly used nano-sized ingredients include #TitaniumDioxide, which may be the most well-known additive. Others, such as #silicon oxide, calcium carbonate, iron oxides and hydroxides, calcium silicate, tricalcium phosphates, and #synthetic #silicas, are only a few of the additives that may be in your pantry right now.

A New Ingredient

Nanotechnology has become widely used in food production and manufacturing since the #1990s, and its components are unimaginably small—one-hundredth the size of a strand of human hair. They make our food more colorful, brighter, creamier, or crunchier, and they keep it fresher for longer as well.

Nano-sized additives also make some of our medicines more effective.

Nanotechnology is used in the manufacturing of #everyday #products, such as electronics, food and food #packaging, #medicine, #toys, #clothing, #sunscreens, #cosmetics, #dietary #supplements, and #much #more.

While they can provide a myriad of benefits, these increasingly popular product enhancers come at a price, according to #consumer groups and #health experts—and that price is our health.

Health Implications

Because these particles are so small, studies have shown that they can breach the #blood-brain barrier. Researchers are already exploring this quality for drugs meant to treat neurological conditions. But when it comes to food, that’s not a feature anyone is asking for. These particles are also able to circulate throughout the body and get absorbed into the bloodstream and organs. They can #penetrate #cell #walls and potentially create #inflammation and #disease.

“They may pass through the #lining #of the #gut and enter the #bloodstream, which may trigger an inflammatory or immune response,” Harvard School of Public Health’s Georgios Pyrgiotakis told WebMD. “They may also build up in various parts of the body, including the #lungs, the #heart, and reproductive organs.”

In a July 2020 study, a group of researchers at the University of Massachusetts Amherst found that titanium dioxide, which is commonly added to #gum, #candy, #drinks, and #desserts, caused changes in the gut #microorganisms of two groups of mice.

Both were given doses of titanium oxide. One group was fed a low-fat diet and the other a high-fat diet. After further testing to isolate the titanium dioxide effect, both groups had inflamed colons, which can lead to abdominal pain and diarrhea. The obese mice had more pronounced symptoms.

Vaccine Technology

Nanotechnology is currently being used in two of the three #mRNA #COVID-19 vaccines being given in the United States today.

There’s a #ipid #nanoparticle coating surrounding the mRNA in the vaccines, which allows them to penetrate the cell’s wall.

“Lipid #nanoparticles are a vital component of the Pfizer/BioNTech and Moderna mRNA COVID-19 vaccines, playing a key role in protecting and transporting the mRNA effectively to the right place in cells,” stated the Chemical Abstracts Service, a division of the American Chemical Society.

“Of the many COVID-19 vaccines under development, the two vaccines that have shown the most promising results in preventing COVID-19 infection represent a new class of vaccine products: They are composed of messenger ribonucleic acid (mRNA) strands encapsulated in lipid nanoparticles (LNP).”

But scientists have continued to call for greater oversight of these substances by the Food and Drug Administration (FDA) because of their size. Because they easily cross the blood-brain barrier, they may damage it by altering the layer of cells that line the inner wall of blood vessels.

FDA Looks Closer

The FDA, the agency charged with overseeing these additives, has begun to weigh the health risks from nano-sized additives.

The agency currently classifies nanoparticles in food with the designation Generally Recognized as Safe (GRAS) if the manufacturer is already using the same ingredient in its larger, conventional form.

“The particle size distribution of a food substance may affect its ability to be absorbed by the body or to migrate from food packaging into food,” the FDA stated in a 2007 guidance document on nanotechnology in food.

“The FDA does not categorically judge all products nanomaterial or otherwise involving application of nanotechnology as intrinsically benign or harmful. The FDA is monitoring the evolving science and has a robust research agenda to help assess the safety and effectiveness of products using nanotechnology.”

In 2011, the FDA Nanotechnology Task Force was created to coordinate its efforts with research scientists in the United States and internationally. Its goals are to train staff in the latest science at state-of-the-art facilities and to encourage collaborative research projects.

“Production and application of nanoparticles in consumer products is at an all-time high due to the emerging field of nanotechnology,” the FDA stated in a 2017 Grand Rounds webcast. “Direct detection and quantification of trace levels of nanoparticles within consumer products is very challenging and problematic.”

Tiny Particles, Growing Problem

By 2020, the FDA reported that applications for the approval of products containing nanotechnology had skyrocketed in the previous 10 years. According to many experts in the United States, there are 1,900 to 2,500 food products that use nanotechnology.

In response to health concerns about these products, countries around the #world have taken steps to limit or #ban some or all nanotechnology in their food.

In 2010, #Canada #banned nanotechnology in #organic food production. Since 2011, the #EuropeanUnion has required all food to be #labeled if it contains #engineered #nanomaterials. In 2015, the bloc required additional testing to ensure health safety.

In 2018, the European Food Safety Commission was petitioned by a group of scientists within the agency to reject the food additive silicon dioxide as safe for consumption because of nanoparticles in it, until a particle size distribution could be confirmed.

Beginning Jan. 1, 2020, #France banned any foods containing #titanium #dioxide from entering the country.

In the United States, the FDA doesn’t require any products produced with nanoparticles to be labeled or banned, and its guidelines recommend oversight on a case-by-case basis. Research on the long-term effects of ingesting nanoparticles remains scant.

This is one of many reasons I don't buy meat at supermarkets.

I buy all my meat from local butcher. I know his meat is Fresh and I don't pay extra for plastic pollution.

But they are Muslims and don't sell pork. So pork is one of the items I buy at Carrefour or Lidl.

Bought some ham to bake it was 1620g, and the package was 148g. Almost 9% of the total weight.

At 9€ a kilo, that is almost 1 euro paid for heavy plastic pollution.

Just created a new wiki page for the project mindfulness-at-the-computer and hoping that this will be useful for others:

Packaging Python Projects

(Looking at setuptools there's been a lot of changes lately, for example there is experimental support for pyproject.toml)

#python #programming #development #deployment #packaging #PythonPackaging

Doppelgänger creates polystyrene substitute from plastic-eating mealworms

Charlotte Böhning and Mary Lempres of design duo Doppelgänger have developed a bioplastic version of polystyrene foam that is made from the exoskeleton of mealworms and breaks down in soil in a couple of weeks.

The material, called Chitofoam, is shock-absorbent, water-resistant and can be formed into cups, foam peanuts and other packaging, much like its fossil-based counterpart.

Doppelgänger created the bioplastic to offer a backyard-compostable alternative to traditional expanded polystyrene (EPS).

Chitofoam can be turned into cups (top image) and packaging materials (above)

Chitofoam can be turned into cups (top image) and packaging materials (above)

Regular EPS, of which Styrofoam is the most well-known brand, is difficult and uneconomical to recycle, meaning it ends up occupying around 30 per cent of the space in our landfills.

"At the end of its short life, polystyrene is not accepted by recycling centres and is undesired by landfills," Lempres told Dezeen. "It is a problematic plastic with no second life that affects future generations, our environment and our future earth."

While polystyrene is made from petroleum-based styrene, which the World Health Organisation has deemed a "probable carcinogen," Chitofoam is derived from a biopolymer called chitin, which mealworms use to build their strong yet pliable exoskeleton.

It can also be formed into packaging peanuts, much like traditional polystyrene

It can also be formed into packaging peanuts, much like traditional polystyrene

Doppelgänger says the bioplastic foam could be made from any mealworm – the larval form of the mealworm beetle – or other insect or crustacean with a chitin-rich shell, such as lobsters and beetles.

Böhning and Lempres made their version from the mealworms living in their own homemade biodigester, which the industrial design students developed to dispose of the polystyrene modelling foam and packaging used in their studio.

This harnesses mealworms' natural ability to digest and break down polystyrene using their gut bacteria, which was documented by researchers from Stanford University in 2015.

Mealworms can safely digest polystyrene plastic

Mealworms can safely digest polystyrene plastic

"It started off quite simply as a tank with 1,000 mealworms in which we put our waste foam, a material that is unfortunately abundant in design school," Böhning said. "It has gradually grown to include tiered-drawers and many more worms."

"The mealworms can help divert polystyrene waste from landfills and natural environments," she continued. "They can safely and efficiently digest the polystyrene foam with no ill effects on their own health."

With Chitofoam, Doppelgänger aims to show that the little bugs could be used not just to degrade existing polystyrene waste but also to create a bioplastic alternative to it.

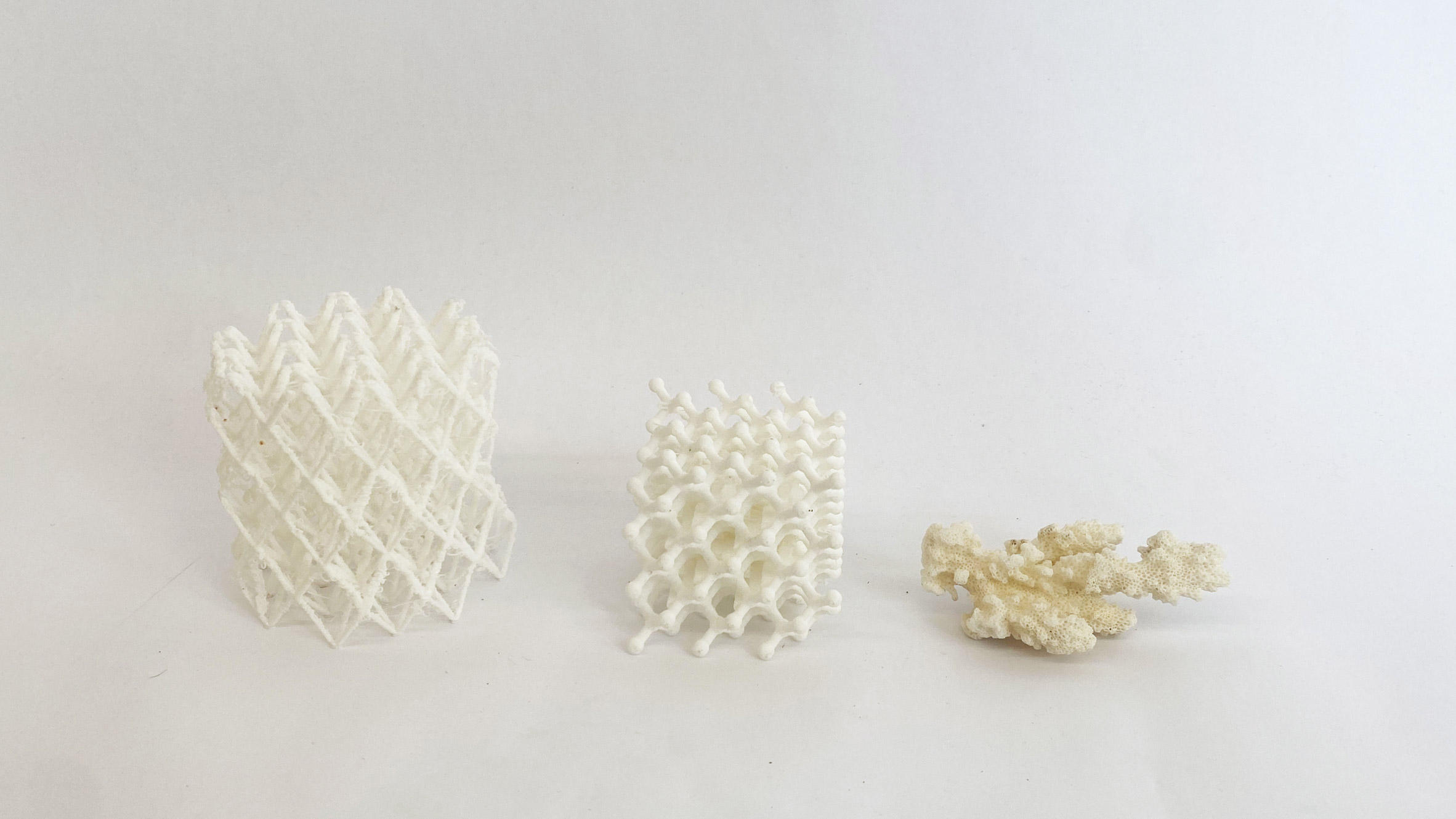

Doppelgänger has modelled the packaging on the shape of coral

Doppelgänger has modelled the packaging on the shape of coral

Once the mealworms have reached the end of their life, the designers collect them from the biodigester and extract the chitin from their exoskeletons by treating them with an alkaline solution, in a process known as deacetylation.

This powdered chitin derivative called chitosan is then dissolved in citric acid, mixed with a waste-derived biopolymer that the studio is keeping under wraps until its patent application has been granted.

Vigorous shaking ultimately gives the mixture its characteristic foamy consistency, which Doppelgänger says is more flexible and elastic than traditional expanded polystyrene while having natural antifungal and antimicrobial properties.

[

Read:

The Dezeen guide to bio-based materials in architecture, design and interiors

](https://www.dezeen.com/2021/12/09/dezeen-guide-biomaterials-architecture-design-interiors/)

Chitofoam can be cast or injection-moulded into shape, much like Styrofoam, but Böhning and Lempres are currently still testing whether the material has the same thermal insulation properties that would allow it to be used to store hot foods and drinks.

As Chitofoam is a thermoplastic it can be melted down and reformed into new products, or placed in soil where it decomposes in two to three weeks.

Doppelgänger says the material has a "high biocompatibility and very low toxicity". But some experts have raised concerns about whether the acidity of bioplastics could throw off the ph balance of soil and water.

The material has shock-absorbent properties thanks to its foamy texture

The material has shock-absorbent properties thanks to its foamy texture

Chitofoam is one of six projects shortlisted for this year's Lexus Design Award, with the winner set to be decided later this spring.

Until then, Doppelgänger is working to further progress the project with the help of a £19,000 budget and guidance from a group of four mentors including designer Sabine Marcelis and Yosuke Hayano of Beijing architecture firm MAD.

The studio's plan is to develop a food product from the protein-rich, plastic-eating mealworms, which would then be packaged in the mealworm bioplastic.

The material could be used as a substitute to traditional polystyrene packaging

The material could be used as a substitute to traditional polystyrene packaging

"Mealworm farming has been highlighted in recent years as an environmentally sustainable solution to malnutrition, particularly in developing rural economies," the studio said.

"Growing edible mealworms is affordable, low-resource and space-efficient. The resultant food source is twice as protein-efficient as beef with zero methane emissions."

In this way, the designers say the mealworms could eventually help to tackle two sustainable development goals at the same time, providing food security and fighting pollution.

Chitin can also be turned into a bioplastic film

Chitin can also be turned into a bioplastic film

Early studies have shown that mealworms that have digested polystyrene can still be used to feed other animals, but more research is necessary on whether they could safely be eaten by humans and whether they could be used to break down plastics at a mass scale.

As the mealworms digest the polystyrene, around half of the fossil carbon that was stored in the plastic is also emitted into the atmosphere as CO2, which could contribute to global warming.

The chitin found in their exoskeletons has been much more widely studied and already turned into a range of different materials including a leather alternative and a bioplastic film.

The post Doppelgänger creates polystyrene substitute from plastic-eating mealworms appeared first on Dezeen.

#all #design #materials #products #technology #plastic #insects #packaging #bioplastic #recycling #polystyrene #doppelgänger

Notpla salvages seaweed by-product to make paper

Sustainable packaging brand Notpla has used seaweed leftover from its own production processes to create paper that can be turned into envelopes and boxes.

Notpla introduced its eponymous product Notpla Paper in collaboration with Canopy, a nonprofit organisation that aims to protect forests and animal species threatened by climate change.

Notpla Paper is made from 30 per cent seaweed by-product

Notpla Paper is made from 30 per cent seaweed by-product

According to its creators, Notpla Paper is made from 30 per cent seaweed by-product, which refers to any secondary product that is made as a result of a production process and is often thrown away and wasted.

Notpla – which is a shortening of "not plastic" – uses pure seaweed to create all of its existing products, which include biodegradable condiment sachets and coating for food containers.

The brand explained that it wanted to find a use for the seaweed leftover from its production processes "to make sure nothing is wasted".

The material can be used as packaging

The material can be used as packaging

"Each of our products uses different extracts of seaweed, leaving the fibrous part of it behind," Notpla design director Karlijn Sibbel told Dezeen.

"This by-product represents a significant amount of pure raw seaweed. From our desire to utilise every part of the seaweed, the idea to upcycle this material came naturally."

The paper can create containers for various products

The paper can create containers for various products

Notpla claimed that using one tonne of seaweed by-product could save up to four tonnes of trees being felled, preventing deforestation.

"From a circular mindset in which waste doesn't exist, we aim to reduce the need for virgin materials as much as possible and therefore prefer the use of by-products," said Sibbel.

"With the need for seaweed extracts in our other product lines, we want to make sure every part of the seaweed is fully valued and used to the best extent."

A minimal wine label made from Notpla Paper

A minimal wine label made from Notpla Paper

The brand said that the remaining 70 per cent of Notpla Paper is composed of a mixture of mainly other recycled materials and a small portion of traditional virgin wood pulp.

"Our design process is firstly driven by an environmental point of view," Sibbel continued. "This means that we use as much seaweed as possible, as little virgin wood as possible and no synthetic additives, which are currently the status quo in papermaking."

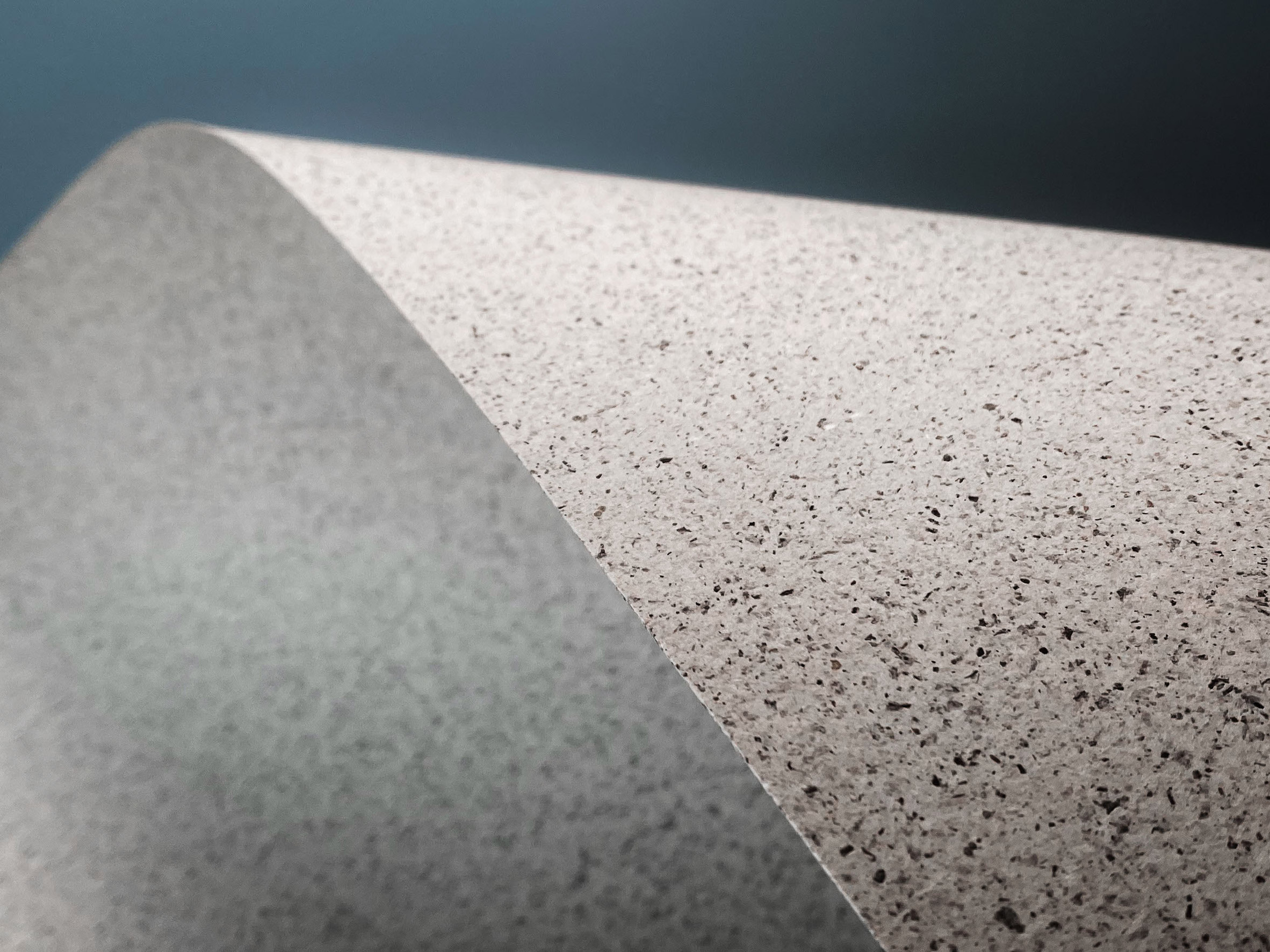

The paper has a speckled appearance

The paper has a speckled appearance

Speckled and neutrally-toned in appearance, Notpla Paper can be used to package products such as hand soap and toothbrushes, as well as to create boxes, envelopes and labels on wine bottles.

Sibbel explained that while the paper currently contains some virgin wood, Notpla aims to create entirely wood-free paper by 2024.

[

Read:

Nienke Hoogvliet launches Zeefier brand to produce natural seaweed dyes for the fashion industry

](https://www.dezeen.com/2021/11/14/zeefier-natural-seaweed-dyes-nienke-hoogvliet/)

While the brand did not specify which materials will be used to achieve this, its intention is to blend alternative fibres with the seaweed by-product to will support the paper's technical properties.

"Our ambition is to alleviate pressure on forests and decrease the environmental impact of paper manufacturing," concluded Sibbel.

Notpla aims to create entirely wood-free paper by 2024

Notpla aims to create entirely wood-free paper by 2024

Notpla Paper is part of Canopy's Pack4Good initiative, a project that is challenging brands to create sustainable alternatives to traditional paper packaging.

Founded in 2014 Rodrigo Garcia Gonzalez and Pierre Paslier while the pair were studying Innovation Design Engineering, Notpla also manufactures biodegradable seaweed packaging, which was shortlisted in the sustainable design category at the 2021 Dezeen Awards.

The images are courtesy of Notpla.

The post Notpla salvages seaweed by-product to make paper appeared first on Dezeen.

#all #design #products #sustainabledesign #paper #packaging #seaweed #circulareconomy #recycling #notpla

It's amazing how unpythonic (and un-Zen-Of-Python) Python packaging is (and has become over time).

I'm trying to make a simple distribution for a single-module non-package.

I'm getting an error "DistutilsFileError: package directory […] does not exist.

Somehow it implicitly derives that package directory from the single module I list in py_modules in the setup.py, obviously by removing the .py ending. I never mention this directory myself ANYWHERE.

All the longer more detailed examples I can find only deal with actual packages, and mention single-module distributions only in passing.

frustrated-ly y'rs - jae

#obhashtags #python #pythonic #unpythonic #packaging #setuptools #whatamess #missthesimplerdays #noloveforthehobbydev

Surgical Mask Boxes

Look for Uniquely Designed Surgical Mask Boxes

The quality and most trusted Surgical Mask Boxes have become an important part of the medical industry. Traditionally designed bundling was using to pack, ship, store, and display surgical products. It is still used by many startup and famous retailers. Because they know that incorrect bundling can create issues and temper mask products badly. Therefore, this factor needs special attention and retailers should contribute to creating safe and ecological boxes that also contribute towards the safe future of the medical industry. So here we reveal and highlight such crucial ways that help in getting these boxes.

Make a proper analysis of quality materials

Surgical masks are designed to protect people from dirt and infectious diseases. Therefore, it is important to keep this product safe from harmful weather conditions. That’s why the retailers should rethink the wrapping ways as it is all about to create physical safety of products. The physical safety of the surgical masks is a crucial element to engage and remain the center of attraction among customers. Using the quality cardboard stock is a critical need that allows creating quality and outstanding bundling to increase customers’ experience with products. For this reason, the manufacturers can collect quality materials to implement personalized and quality strategies of products. Based on quality and long-lasting materials, the manufacturers can make the experiment of keeping mask products safe and secured from external and internal damages.

Adopt Eco-friendly leads in packaging

Most of the time, the retailers have become careless about choosing the ecological bundling for surgical products. Although, consumers are looking for green bundling ideas that influence the environment safety and functional standpoint of the medical products and we know that consumers’ encounters’ with many products but choosing products in Eco-friendly bundling is the prime factor of increasing sales. The majority of customers get pulled towards safe products that are a wrap in green Customize Boxes. Therefore, creating ecological slogans and labels will ensure the right connection with customers. So manufacturers and retailers will never ignore the Eco-friendly factor that more likely to associate with Eco-conscious customers effectively. It’s especially crucial to make a logical and responsible image of the brand in the medical field.

Make it travel friendly

As mentioned earlier, quality bundling is an excellent tool for increasing products’ awareness and safety at a time. Therefore, the quality casing would ship and carry mask products most safely and it could be the usual way to keep along with the safety and security factor in masks products during shipping. We know that fragile and bad quality bundling can cause huge clutter because it is always difficult to manage and prevent masks from damages. Therefore, having a sturdy and lockable bundling is the best idea to ensure the safe shipping of medical products. This is the positive sign of safety and quality of medical products. For this reason, the manufacturers should use quality materials that have the power to absorb moisture and shock from the environment to keep products safe. So it will allow consumers to store valuable masks in it and bring more sales for the retailers.

Find bespoke approach in printing

Indeed, the smart and creative printing and customization solution will heighten the level of attraction. For the authentic display of surgical products, pharmaceutical manufacturers should consider adopting the authentic and developed customized solution. For example, now manufacturers can use digital tools to design an impressive and fascinating bundling that ensure to remain in the center of attention. For adding more smart packaging features, the designers can pursue genuine colors, finishing, designs, and themes for the distinguished modifications. We can say that printing and customization will allow us to add a more bespoke approach in attractive bundling. That stands the medical masks more aesthetically different from the crowds. So just add a quality layered approach for the products’ security and practicality at the same time. Though, this will create smart communication and display solutions for retailers.

Choosing unique styles in packaging

To implement a direct connection, the manufacturers should consider the unique styling factor in packaging. It includes using appropriate size and stylish structure features in these boxes for the security of potent products. Having a fancy and easy-to-use bundling will available to preserve masks products on the shelf and even help customers to identify their products instantly. It is a positive and creative point to have everything in front of the customer. Further, this will bring innovation and novelty in the purchase behavior of customers as well. So the bundling should be designed according to the customers’ needs.

Reconsider marketing idea

Do you want to give your medical products strong and impactful value? Then set a promotional strategy to reflect the real image of the medical store and retain customers’ for a long time. Due to this reason that Custom Printed Sanitizer Boxes are considered a part of good marketing and make influence on customers’ perception. Especially when it designed with a logo and slogans, then it will cause an intense emotional connection of customers. The marketing cues on the bundling will win the positive emotions of customers. On the other hand, it increases their instinct to buy products. For surgical masks, it is vital to understand customers’ interests and preferences. And then design a logo-embossed bundling with accurate product information and data that can improve products’ sales as well. So if you are in the medical industry, then don’t forget to have an effective marketing strategy that helps shoppers to quickly identify your company name while display in the market.

#SurgicalMaskBoxes #CustomizeBoxes #CustomPrintedSanitizerBoxes #MaskBoxes #PrintedBoxes #SanitizerBoxes #Masksboxes #PrintingBoxes #SanitizerPackaging #MaskPackaging #PrintedPackaging #PrintedSanitizerBoxes #Custommaskboxes #CustomPackaging #HandSanitizerBoxes #PrintedMaskBoxes #CustomPrintedPackaging #CustomBoxeswithLogo #CustomPackagingBoxes #CustomBoxesWholesale #BoxeswithLogo #CustomProductBoxes #CustomPackagingBoxeswithLogo #PrintedBoxesWholesale #WholesalePrintedBoxes #PackagingCustomLogo #PackagingBoxeswithLogo #PrintedBoxeswithLogo #PackagingBoxes #Packaging #Boxes

The manufacturers should comply with the high standards in Customize Boxes and reveal the most well-known benefits of products. So switching a simple bundling into a bespoke box will bring great marketing benefits for the medical industry.

#CustomizeBoxes #PrintedBoxes #PrintedPackaging #Packaging #CustomPrintedPackaging #CustomBoxeswithLogo

Garbage In, Garbage Out

A white actor in redface shed a tear, and our problem was reduced to a fairy tale.

https://thebaffler.com/latest/lies-damned-lies-and-recycling-king