"Largest wooden building in Iceland" to occupy landfill site in Reykjavík

Architecture studios Jakob+MacFarlane and T.ark have designed a low-carbon cross-laminated timber building called Living Landscape that will transform a landfill site in Iceland's capital city.

Slated for completion in 2026, the 26,000-square-metre mixed-use building is set to become the "largest wooden building in Iceland" once complete.

Living Landscape has been developed by French studio Jakob+MacFarlane and local studio T.ark to give new life to the polluted landscape and offer a prototype for similar future developments in Reykjavík.

"The project recreates a fragment of authentic natural landscape on top of polluted land to compensate for years of pollution and heal the man-made damage to what has once been a beautiful coastal landscape," Jakob+MacFarlane told Dezeen.

Project is a Reinventing Cities winner

Once complete, the project will contain a mix of housing for students, elderly people and families, alongside workspaces, daycare facilities and local shops.

It is among the 49 winning projects of the Reinventing Cities competition, which was organised by global network C40 Cities to encourage the transformation of underused urban spaces into "beacons of sustainability and resiliency".

The projects strive to help urban areas meet the goals of the 2015 Paris Agreement on climate change by minimising carbon emissions.

Above: Living Landscape will be a low-carbon cross-laminated timber building. Top image: it will transform a landfill site in Iceland

Above: Living Landscape will be a low-carbon cross-laminated timber building. Top image: it will transform a landfill site in Iceland

The Reinventing Cities programme encourages projects to minimise both embodied carbon – emissions generated during material production and construction – and operational carbon, which are emissions caused by the building's usage.

Jakob+MacFarlane and T.ark are aiming for net-zero emissions, which involves eliminating all possible emissions and offsetting any that cannot be eliminated by removing carbon from the atmosphere.

CLT will reduce embodied carbon "by almost 80 per cent"

According to Jakob+MacFarlane, this will be achieved in part by using a prefabricated cross-laminated timber (CLT) structure.

"The CLT construction reduces the embodied carbon of external walls by almost 80 per cent compared to a typical concrete structure used in Iceland," the studio explained.

"The [remaining] embodied emissions will be offset through either wetland recovery or forestry, making the building effectively carbon neutral."

Among the other materials used in the building will be Panoblocs, a type of prefabricated and insulated wall panel with a wooden exterior, which can be easily removed and adapted.

[

Read:

Urban developments that "strive for zero carbon" to start on site in Milan, Paris, Reykjavik and Oslo

](https://www.dezeen.com/2021/07/07/carbon-c40-cities-reinventing-cities-competition-zero-carbon/)

Living Landscapes' operational carbon emissions are expected to be minimal, due to high levels of insulation and use of waste-heat recovery systems and thermostat-controlled underfloor heating.

However, the energy it will require will be sourced from an existing district electricity and heat network powered by renewable hydropower and geothermal energy sources.

Nature to be reintroduced to site

Reintroducing nature to the old landfill site will also be a key part of the scheme. There will be an undulating roof garden and farm, alongside a large central courtyard designed as a communal park for the residents.

"The idea of living with and around nature is key to our project," said Jakob+MacFarlane.

The courtyard will be modelled on Icelandic landscapes, incorporating a mix of rocks, water and plants, which is hoped to encourage insects and birds to occupy the site.

"We aim to enable a fully functioning local ecosystem composed of earth and rocks, water and plants, insects and birds," the studio explained. "Protected from freezing by geothermal heat, this green oasis will develop its own microclimate and, hopefully, become a new generator of life."

[

Read:

Arney Fender Katsalidis to transform Tuscolana railway site into low-carbon 15-minute city

](https://www.dezeen.com/2021/08/19/arney-fender-katsalidis-c40-cities-rome-competition-architecture/)

Living Landscape is now being continually developed by Jakob+MacFarlane and T.ark with landscape architects Landslag and environmental experts EFLA.

Another winner of the Reinventing Cities competition was architect Arney Fender Katsalidis, who is developing a low-carbon neighbourhood in Rome. The mixed-use project will transform a disused railway site, make use of biomaterials and will feature reversible buildings.

The post "Largest wooden building in Iceland" to occupy landfill site in Reykjavík appeared first on Dezeen.

#residential #publicandleisure #all #architecture #iceland #reykjavík #jakobmacfarlane #woodenarchitecture #crosslaminatedtimber #masstimber #reinventingcities #carbonneutraldesign

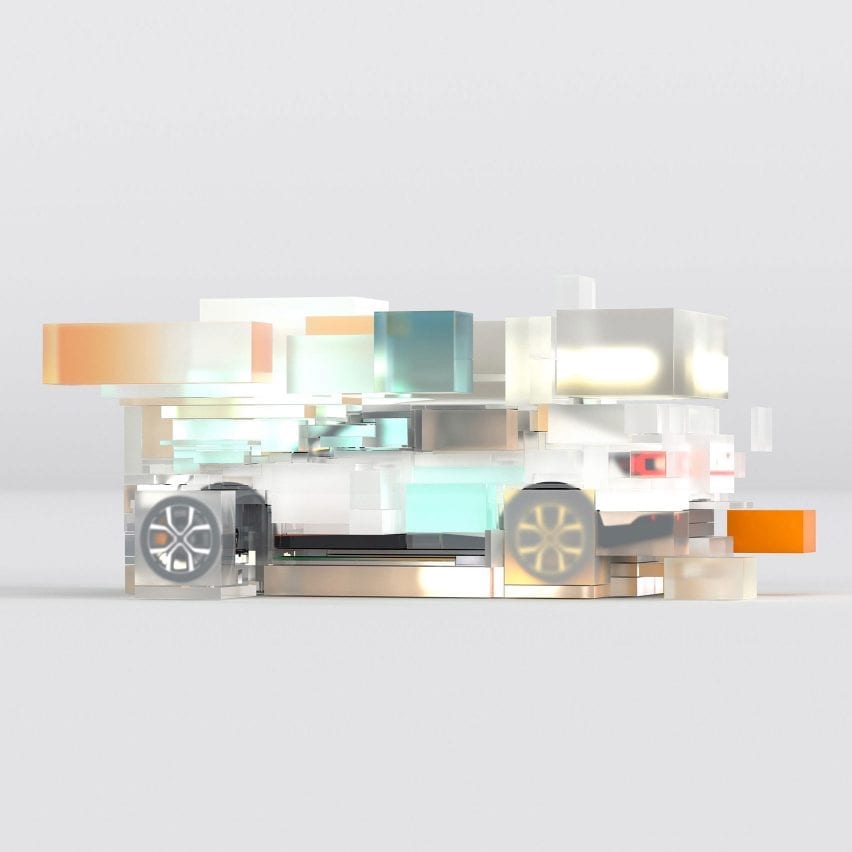

Above: the Polestar 2 is the brand's current electric vehicle. Top: Polestar visualised the emissions associated with its different components in a video made by Wang & Söderström

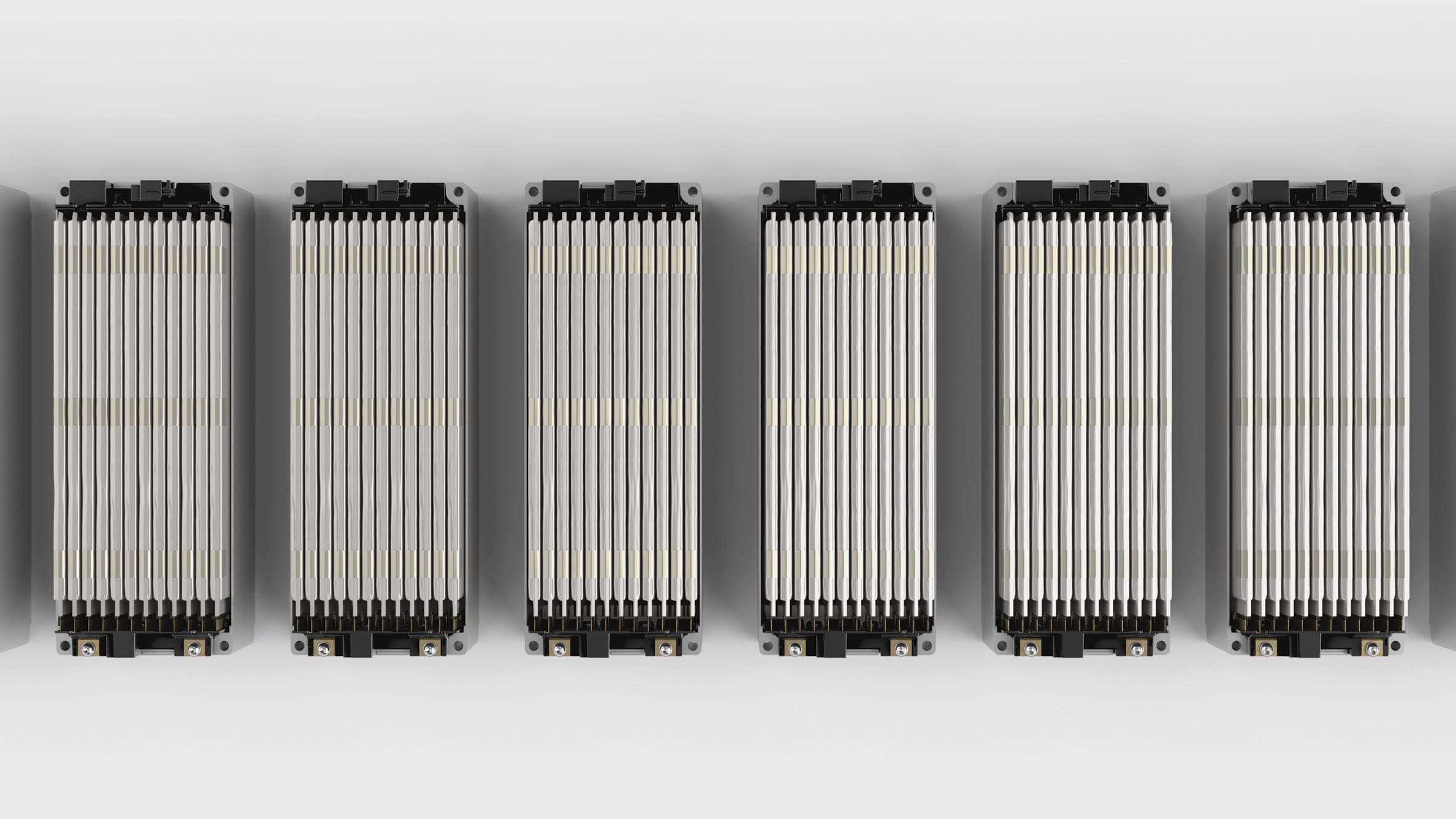

Above: the Polestar 2 is the brand's current electric vehicle. Top: Polestar visualised the emissions associated with its different components in a video made by Wang & Söderström The battery pack of the Polestar 2 contains emissions-intensive metals

The battery pack of the Polestar 2 contains emissions-intensive metals Polestar 0 aims to emit zero tonnes (0t) of carbon dioxide equivalent (CO2e)

Polestar 0 aims to emit zero tonnes (0t) of carbon dioxide equivalent (CO2e) The carmaker will display life-cycle assessment results prominently in dealerships

The carmaker will display life-cycle assessment results prominently in dealerships