Canoo's electric and extendable Pickup truck includes pop-out workspaces

US automotive start-up Canoo has created an all-electric pickup truck with a streamlined look and hidden utility features as one of its first vehicles.

The Canoo Pickup conceals a range of features such as storage, workbenches and charging points within a pared-back chassis.

The Pickup truck is Canoo's third vehicle to be built on the same platform

The Pickup truck is Canoo's third vehicle to be built on the same platform

It also includes an extendable flatbed, so it can offer the payload capacity of a much bigger truck.

It is one of the first vehicles designed by Canoo, which set out to not only electrify the classic pickup truck but imagine ways the model could help users in their work or weekend trips.

The truck includes an extendable flatbed that can go from six to eight feet

The truck includes an extendable flatbed that can go from six to eight feet

For instance, where the engine would traditionally be at the front of the truck, there is a fold-out workbench, with storage compartments and power sockets points for charging tools.

There are also similar flip-down tables with sockets built into the side of the truck, along with more storage and a step to aid roof access.

Where the engine would usually be, there is storage space and a fold-down worktable with power sockets

Where the engine would usually be, there is storage space and a fold-down worktable with power sockets

The modular truck bed can be enlarged from six to eight feet in length by pulling out the extension at the rear, which includes matching space-dividers to help organise items.

There is also versatility built into the cab, which has two seats in front and a rear that can be configured for various uses or filled with additional seats.

The side of the vehicle also has concealed features

The side of the vehicle also has concealed features

The cab and truck bed can also accommodate camper shells, so the Pickup can be adapted for mobile housing on recreational trips.

Other features of the cabin include wide-angle viewing through the windscreen and a configurable pegboard for cupholders, racks and device connections.

According to tthe brand, Canoo Pickup's features were partly enabled by the truck's engineering, which packs the technology needed to power the vehicle into a relatively tight space.

Canoo set out to give the truck a streamlined exterior

Canoo set out to give the truck a streamlined exterior

The Pickup is engineered on the company's tested Multi-Purpose Platform (MPP1), which it is currently using across all of its vehicles.

Canoo claims it integrates all the electric powertrain components in a flat and efficient manner, creating more room for other functions.

"Traditional EV platforms have power units, shock towers and mechanical steering columns that protrude into the vehicle and take up space," said Canoo.

"By incorporating steer-by-wire and other space-saving technologies, the thin leaf spring-based platform contains a full powertrain and motor which results in a flatbed size comparable to America's bestselling pickup truck on the footprint of a compact car."

The truck bed also has built-in storage and organisation features

The truck bed also has built-in storage and organisation features

Among the Pickup's other features are a modular roof rack and integrated tow hooks, skid plates and fog lights in the bumpers.

There is no logo on the outside of the vehicle, with Canoo's signature headlights and tail lights serving as a brand identifier instead.

The cab combines environmentally conscious materials with transparent sections that show the vehicle's inner workings

The cab combines environmentally conscious materials with transparent sections that show the vehicle's inner workings

The interior combines environmentally conscious material choices with sections of transparency to showcase the engineering components that are usually hidden.

The headliner fabric is derived from recycled PET bottles, while the floor material is made from recycled car tires and rubber, and the seats are upholstered in a durable alternative to leather.

The cab provides good visibility for the driver

The cab provides good visibility for the driver

Canoo plans to rollout the vehicle in 2023 or later.

"Our pickup truck is as strong as the toughest trucks out there and is designed to be exponentially more productive," said Canoo CEO Tony Aquila.

"This truck works for you. We made accessories for people who use trucks – on the job, weekends, adventure."

The Pickup is compatible with camper shells so it can be transformed into a mobile home

The Pickup is compatible with camper shells so it can be transformed into a mobile home

Canoo was founded in 2017 and formerly envisioned operating with a vehicle subscription model, but has now shifted to commercial sales.

Its Pickup ttruck is shortlisted in the product design category of the Dezeen Awards, alongside Nendo's build-your-own football and Playfool's Forest Crayons containing the subtle colours of Japanese wood.

Photography is by Richard Thompson III.

The post Canoo's electric and extendable Pickup truck includes pop-out workspaces appeared first on Dezeen.

#transport #all #design #technology #vehicles #electricvehicles

Airlander 10 went viral in 2016 when it was nicknamed the "flying bum"

Airlander 10 went viral in 2016 when it was nicknamed the "flying bum" A new hybrid-electric version could have less carbon impact

A new hybrid-electric version could have less carbon impact The airship could be a less carbon-intensive alternative to inter-city flights

The airship could be a less carbon-intensive alternative to inter-city flights Airlander 10 would produce 75 per cent fewer emissions than a jet plane

Airlander 10 would produce 75 per cent fewer emissions than a jet plane

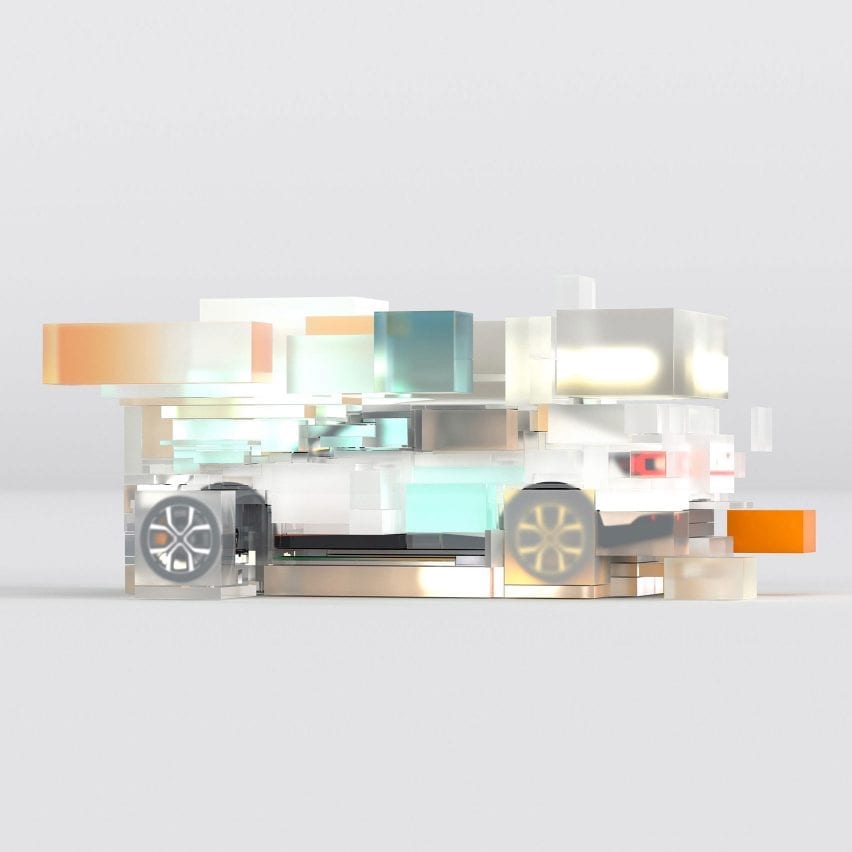

Above: the Polestar 2 is the brand's current electric vehicle. Top: Polestar visualised the emissions associated with its different components in a video made by Wang & Söderström

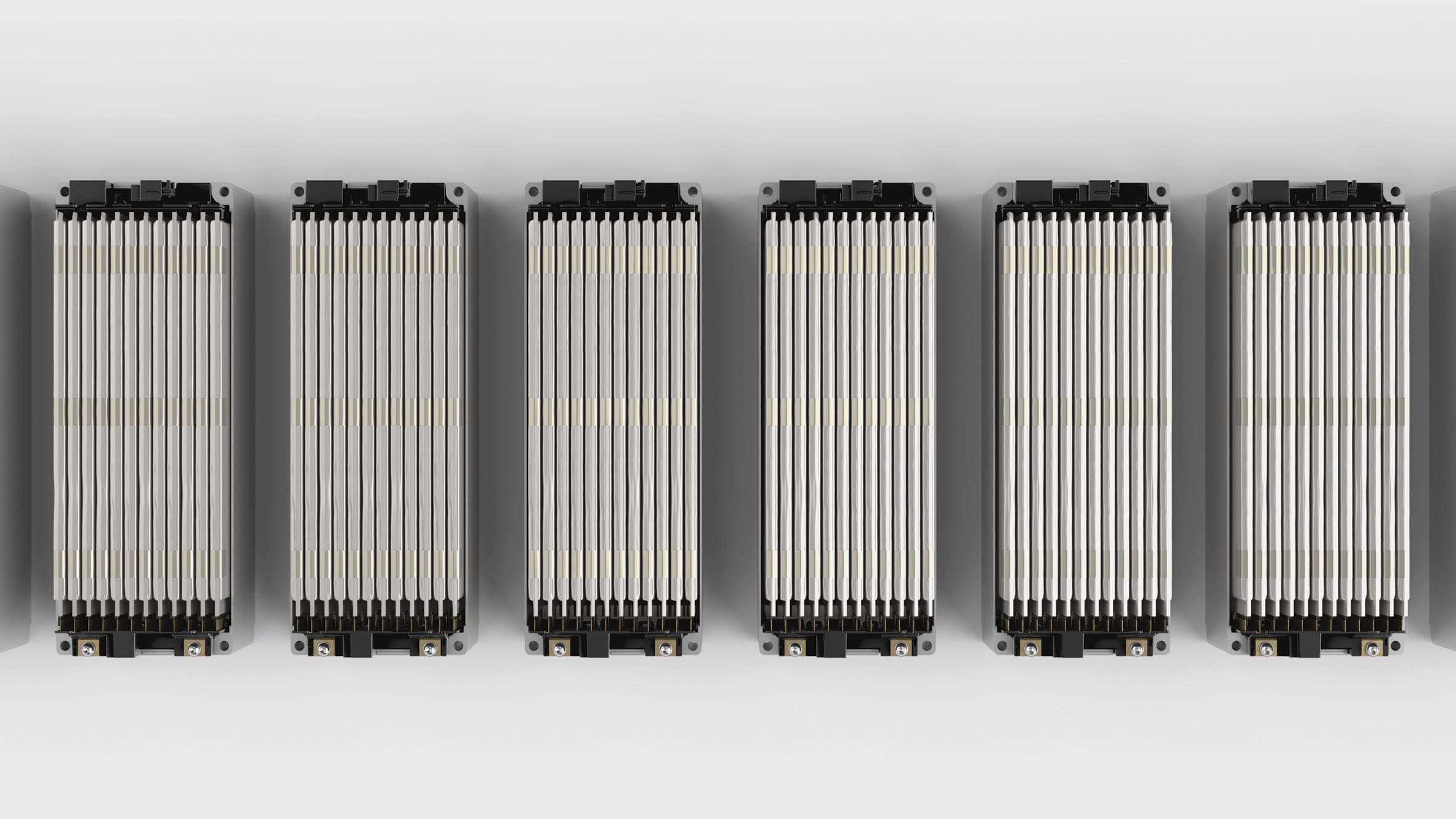

Above: the Polestar 2 is the brand's current electric vehicle. Top: Polestar visualised the emissions associated with its different components in a video made by Wang & Söderström The battery pack of the Polestar 2 contains emissions-intensive metals

The battery pack of the Polestar 2 contains emissions-intensive metals Polestar 0 aims to emit zero tonnes (0t) of carbon dioxide equivalent (CO2e)

Polestar 0 aims to emit zero tonnes (0t) of carbon dioxide equivalent (CO2e) The carmaker will display life-cycle assessment results prominently in dealerships

The carmaker will display life-cycle assessment results prominently in dealerships