One person like that

#structural

3D Printing Hack Leverages Vase Mode Structurally

Conceptually, FDM 3D printing is quite a simple process: you define a set of volumes in 3D space, then the slicing software takes a cut through the model at ever-increasing heights, works out where the inner and outer walls are, and then fills in the inside volume sparsely in order to tie the walls together and support the top layers that are added at the end.

But as you will find quite quickly, when models get larger and more complex, printing times can quickly explode. One trick for large models with simple shapes but very low structural needs is to use so-called 'vase mode', which traces the outline of the object in a thin, vertical spiral. But this is a weak construction scheme and allows only limited modelling complexity. With that in mind, here's [Ben Eadie] with a kind-of halfway house technique (video, embedded below) that some might find useful for saving on printing time and material.

This solid shape is mostly cut-through to make supporting ribs between the walls of the shell

This solid shape is mostly cut-through to make supporting ribs between the walls of the shell

The idea is to use vase mode printing, but by manipulating the shell of the model, adding partially cut-through slots around the perimeter, and critically, adding one slot that goes all the way.

First you need a model that has an inner shell that follows the approximate shape of the outer, which you could produce by hollowing out a solid, leaving a little thickness. By making the slot width equal to half the thickness of the nozzle size and stopping the slots the same distance from the outer shell, vase mode can be used to trace the outline of shape, complete with supporting ribs in between the inner and outer walls of the shell.

Because the slot is narrower than the extrudate, the slot walls will merge together into one solid rib, tying the objects' walls to each other, but critically, still allowing it to be printed in a continuous spiral without any traditional infill. It's an interesting idea, that could have some merit.

There are other ways to stiffen up thing printed parts, such as using surface textures, But if you're fine with the thin shell, but want to have a little fun with it, you can hack the g-code to make some really interesting shapes.

#3dprinterhacks #3dprinting #structural #supportingribs #vasemode

2 Shares

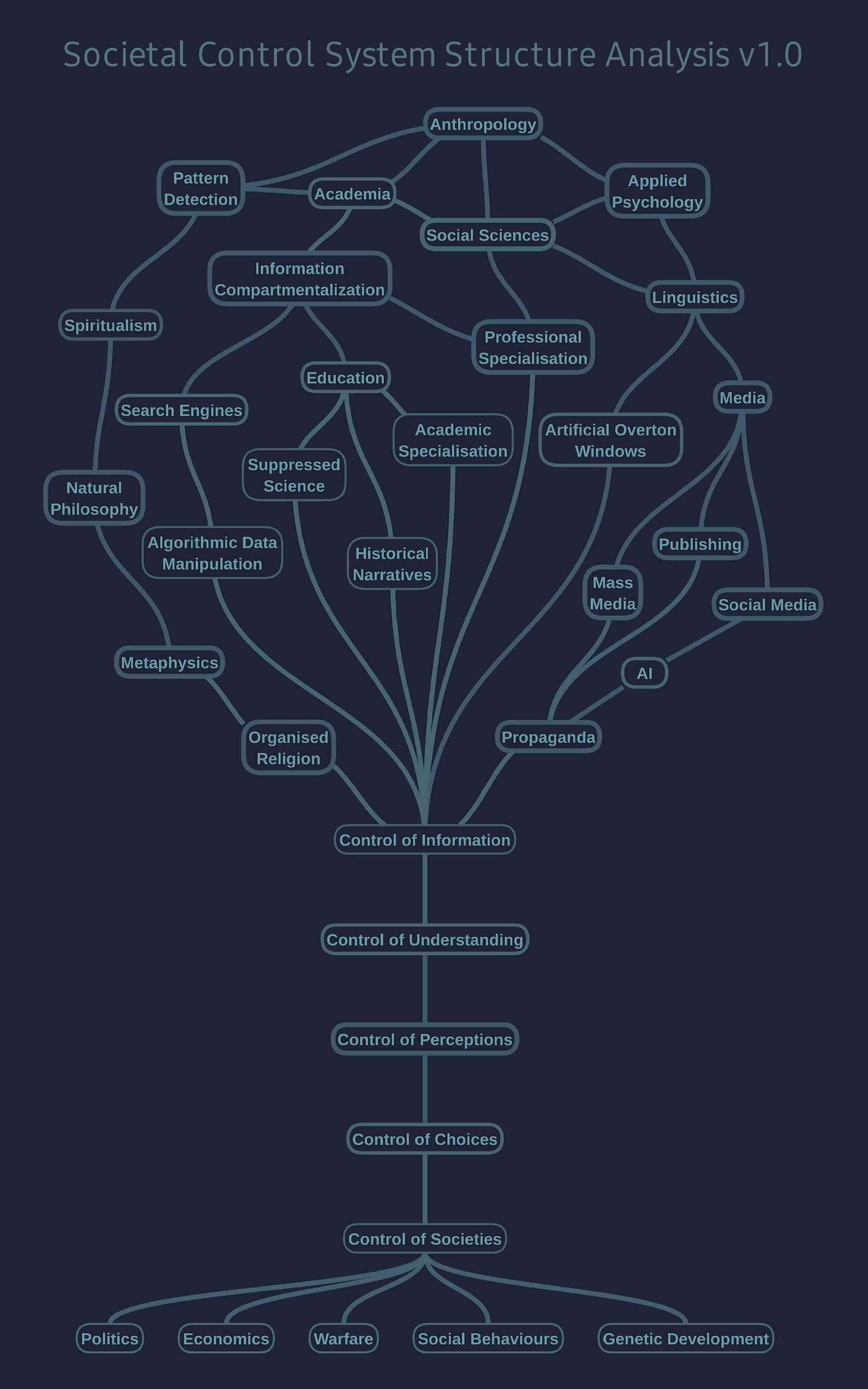

My initial attempt to visually describe the fundamental structure of information control used by the upper echelons of the West's societal power hierarchies to control information & ultimately the societies. Verson 1. Input welcome.

#structure #structural #system #systematic #systemofcontrol #control #informationcontrol #education #compartmentalization #specialization #societalcontrol #societalsystems #powerhierarchy #hierarchy #massmedia #msm #overtonwindow #propaganda #ai #linguistics #academia #psychology #appliedpsychology #anthropology #information #understanding #perception #choices #ontology #epistemology #freedom #liberty #humanity #humanrights #plutocracy #oldmoney #scions #plutocrats #elitists #elites #globalists #socialengineering #socialengineers

One person like that

6 Comments