"The tiny ultrabright laser that can melt steel".

Allegedly in 2016, the Japanese government announced a plan for Society 5.0. If you're wondering what the first 4 were, they were 1: hunter/gatheres, 2: agrarian, 3: industrial, 4: the information age -- the end of which is fast approaching! Bringing us to Society 5: on-demand physical products. (Also robot caretakers, but never mind that -- you need lasers for on-demand physical products!)

"The lasers of Society 5.0 will need to meet several criteria. They must be small enough to fit inside everyday devices. They must be low-cost so that the average metalworker or car buyer can afford them -- which means they must also be simple to manufacture and use energy efficiently. And because this dawning era will be about mass customization (rather than mass production), they must be highly controllable and adaptive."

"Semiconductor lasers would seem the perfect candidates, except for one fatal flaw: They are much too dim."

"Of course, other types of lasers can produce ultrabright beams. Carbon dioxide and fiber lasers, for instance, dominate the market for industrial applications. But compared to speck-size semiconductor lasers, they are enormous. A high-power CO2 laser can be as large as a refrigerator. They are also more expensive, less energy efficient, and harder to control."

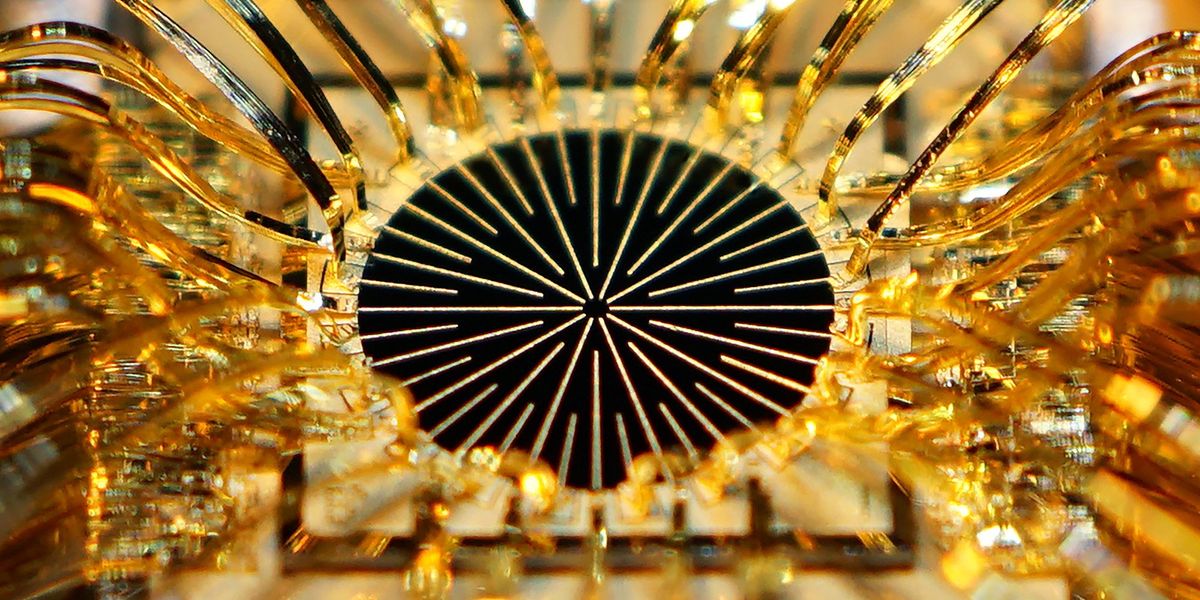

"Over the past couple of decades, our team at Kyoto University has been developing a new type of semiconductor laser that blows through the brightness ceiling of its conventional cousins. We call it the photonic-crystal surface-emitting laser, or PCSEL (pronounced 'pick-cell'). Most recently, we fabricated a PCSEL that can be as bright as gas and fiber lasers -- bright enough to quickly slice through steel -- and proposed a design for one that is 10 to 100 times as bright. Such devices could revolutionize the manufacturing and automotive industries. If we, our collaborating companies, and research groups around the world can push PCSEL brightness further still, it would even open the door to exotic applications like inertial-confinement nuclear fusion and light propulsion for spaceflight."

That paragraph doesn't mention the size. 3 mm. As in, 3 millimeters. A lot smaller than a refrigerator.

The rest of the article describes -- pretty decently for lay people -- how these PCSEL lasers work.

"At certain wavelengths determined by the groove spacing, light refracts through and partially reflects off each interface. The overlapping reflections combine to form a standing wave that does not travel through the crystal."

"In a square lattice such as that used in PCSELs, air holes bend light backward and sideways. The combination of multiple such diffractions creates a 2D standing wave. In a PCSEL, only this wave is amplified in the active layer, creating a laser beam of a single wavelength."