Charlotte Böhning and Mary Lempres of design duo Doppelgänger have developed a bioplastic version of polystyrene foam that is made from the exoskeleton of mealworms and breaks down in soil in a couple of weeks.

The material, called Chitofoam, is shock-absorbent, water-resistant and can be formed into cups, foam peanuts and other packaging, much like its fossil-based counterpart.

Doppelgänger created the bioplastic to offer a backyard-compostable alternative to traditional expanded polystyrene (EPS).

Chitofoam can be turned into cups (top image) and packaging materials (above)

Chitofoam can be turned into cups (top image) and packaging materials (above)

Regular EPS, of which Styrofoam is the most well-known brand, is difficult and uneconomical to recycle, meaning it ends up occupying around 30 per cent of the space in our landfills.

"At the end of its short life, polystyrene is not accepted by recycling centres and is undesired by landfills," Lempres told Dezeen. "It is a problematic plastic with no second life that affects future generations, our environment and our future earth."

While polystyrene is made from petroleum-based styrene, which the World Health Organisation has deemed a "probable carcinogen," Chitofoam is derived from a biopolymer called chitin, which mealworms use to build their strong yet pliable exoskeleton.

It can also be formed into packaging peanuts, much like traditional polystyrene

It can also be formed into packaging peanuts, much like traditional polystyrene

Doppelgänger says the bioplastic foam could be made from any mealworm – the larval form of the mealworm beetle – or other insect or crustacean with a chitin-rich shell, such as lobsters and beetles.

Böhning and Lempres made their version from the mealworms living in their own homemade biodigester, which the industrial design students developed to dispose of the polystyrene modelling foam and packaging used in their studio.

This harnesses mealworms' natural ability to digest and break down polystyrene using their gut bacteria, which was documented by researchers from Stanford University in 2015.

Mealworms can safely digest polystyrene plastic

Mealworms can safely digest polystyrene plastic

"It started off quite simply as a tank with 1,000 mealworms in which we put our waste foam, a material that is unfortunately abundant in design school," Böhning said. "It has gradually grown to include tiered-drawers and many more worms."

"The mealworms can help divert polystyrene waste from landfills and natural environments," she continued. "They can safely and efficiently digest the polystyrene foam with no ill effects on their own health."

With Chitofoam, Doppelgänger aims to show that the little bugs could be used not just to degrade existing polystyrene waste but also to create a bioplastic alternative to it.

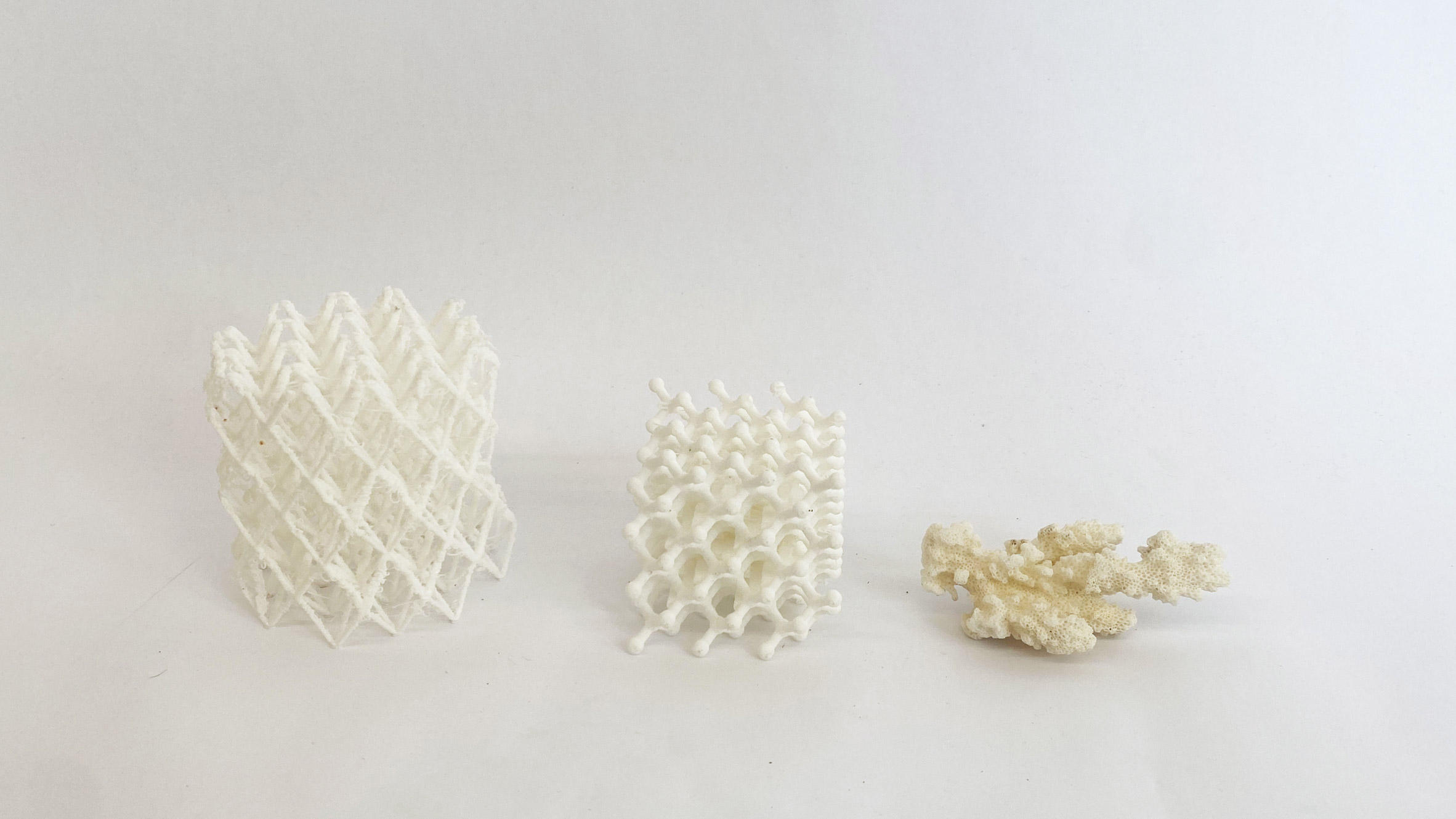

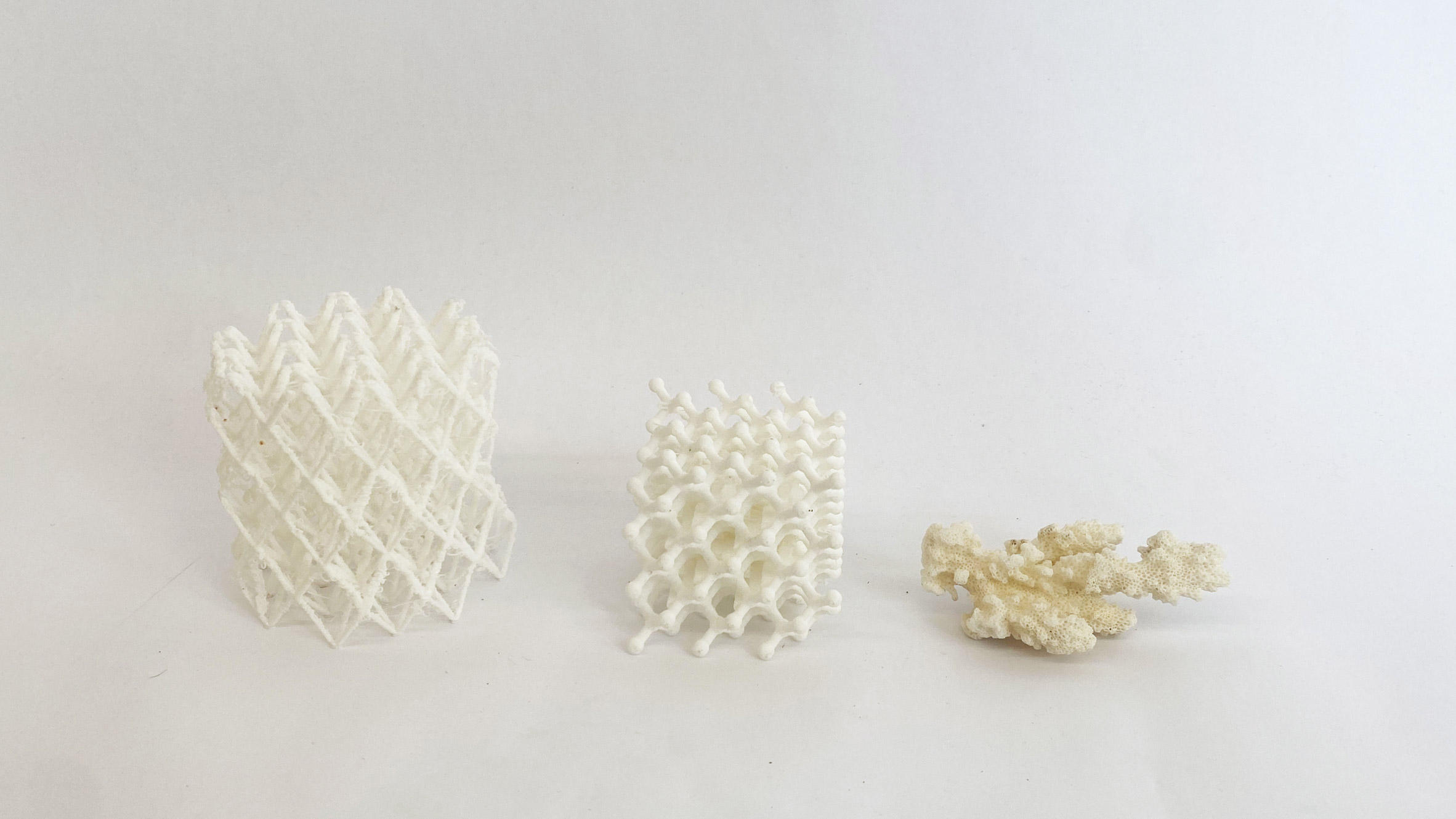

Doppelgänger has modelled the packaging on the shape of coral

Doppelgänger has modelled the packaging on the shape of coral

Once the mealworms have reached the end of their life, the designers collect them from the biodigester and extract the chitin from their exoskeletons by treating them with an alkaline solution, in a process known as deacetylation.

This powdered chitin derivative called chitosan is then dissolved in citric acid, mixed with a waste-derived biopolymer that the studio is keeping under wraps until its patent application has been granted.

Vigorous shaking ultimately gives the mixture its characteristic foamy consistency, which Doppelgänger says is more flexible and elastic than traditional expanded polystyrene while having natural antifungal and antimicrobial properties.

[

Read:

The Dezeen guide to bio-based materials in architecture, design and interiors

](https://www.dezeen.com/2021/12/09/dezeen-guide-biomaterials-architecture-design-interiors/)

Chitofoam can be cast or injection-moulded into shape, much like Styrofoam, but Böhning and Lempres are currently still testing whether the material has the same thermal insulation properties that would allow it to be used to store hot foods and drinks.

As Chitofoam is a thermoplastic it can be melted down and reformed into new products, or placed in soil where it decomposes in two to three weeks.

Doppelgänger says the material has a "high biocompatibility and very low toxicity". But some experts have raised concerns about whether the acidity of bioplastics could throw off the ph balance of soil and water.

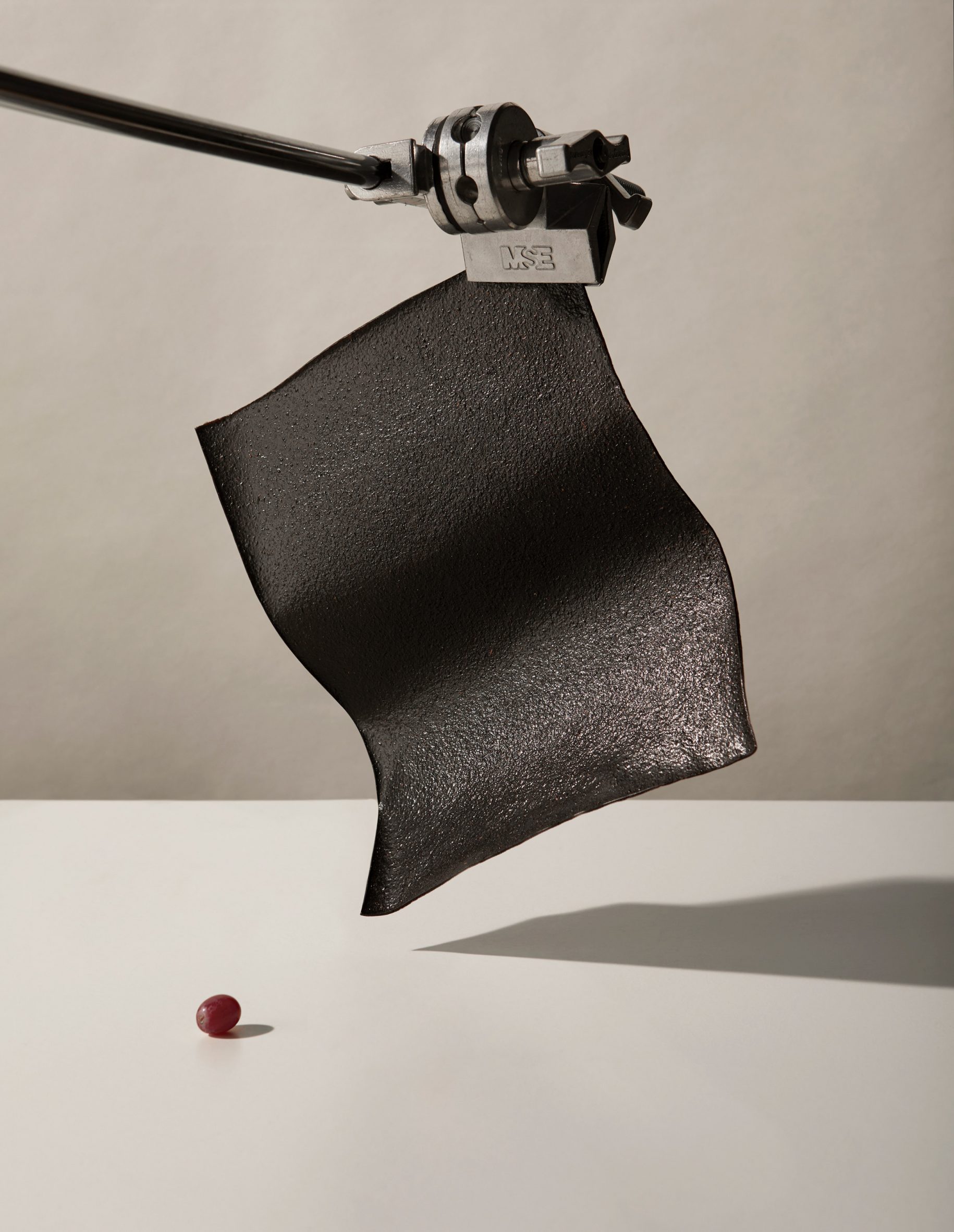

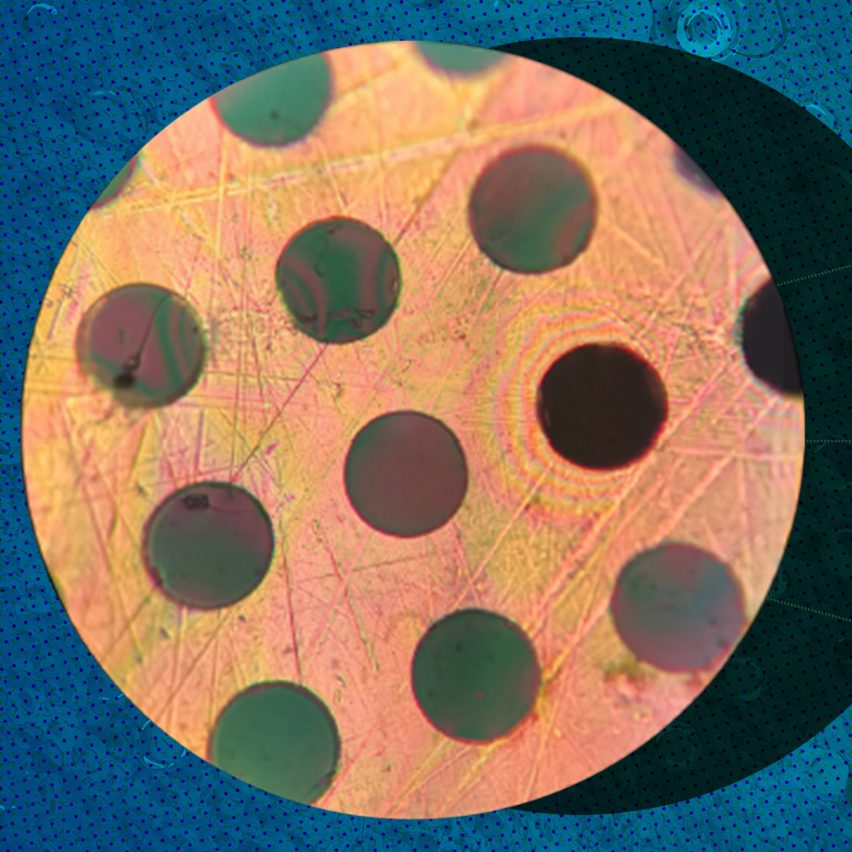

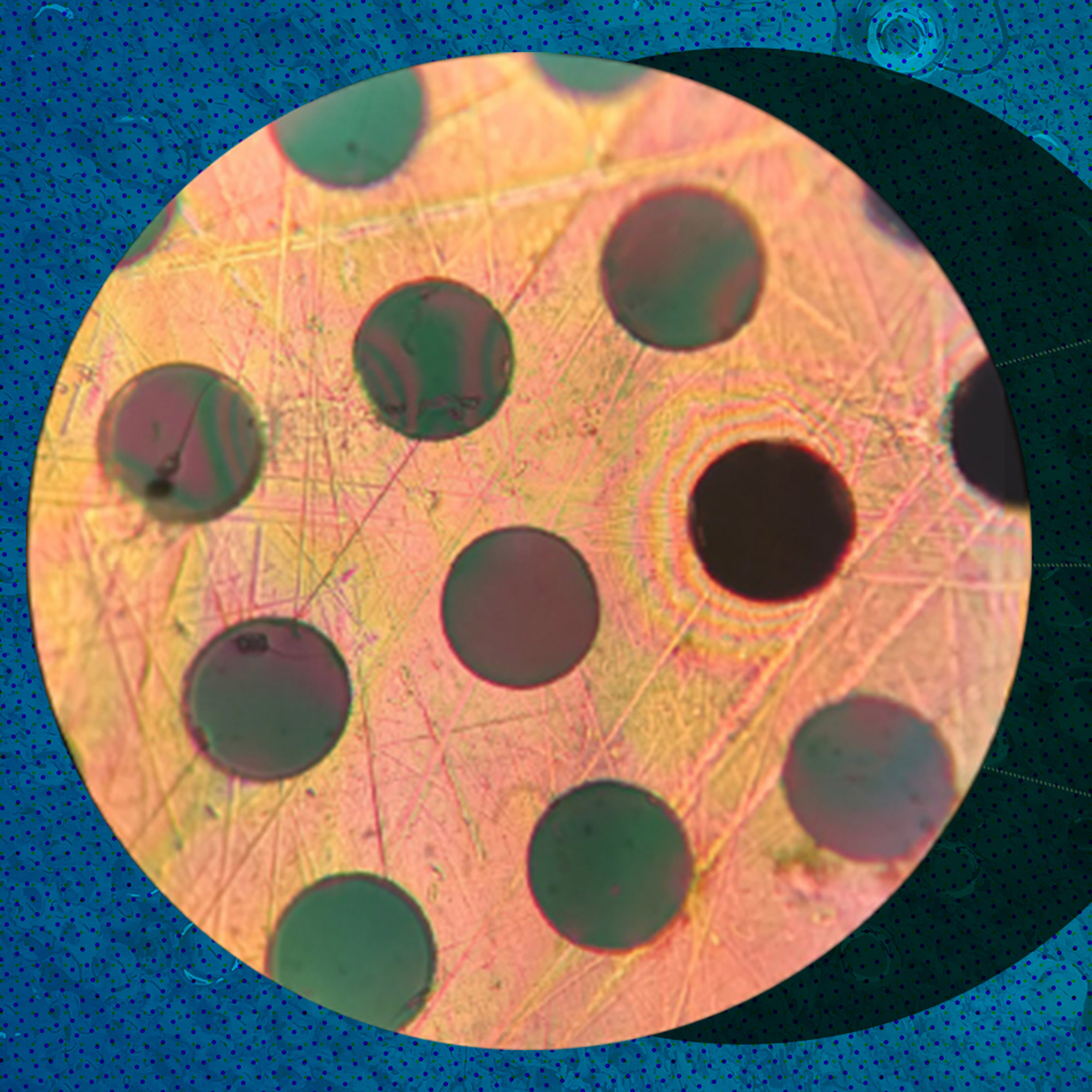

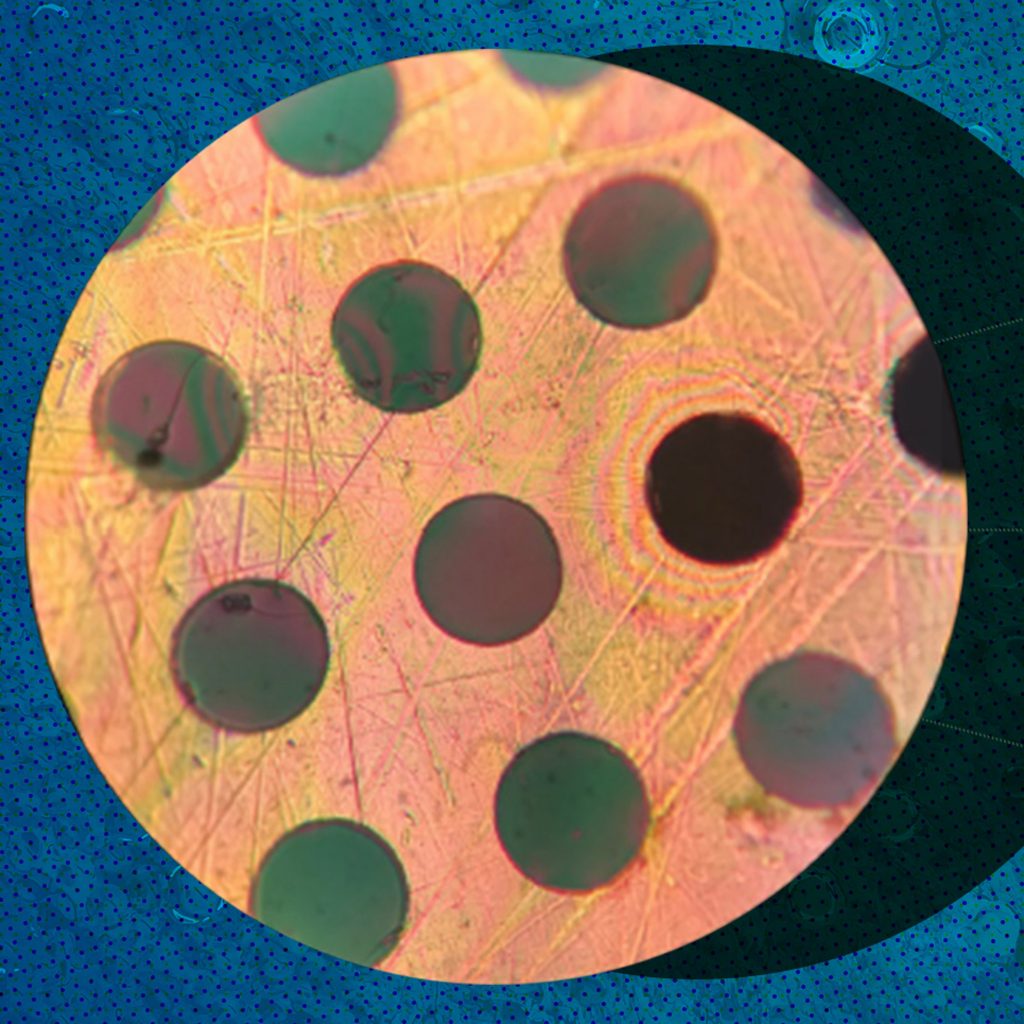

The material has shock-absorbent properties thanks to its foamy texture

The material has shock-absorbent properties thanks to its foamy texture

Chitofoam is one of six projects shortlisted for this year's Lexus Design Award, with the winner set to be decided later this spring.

Until then, Doppelgänger is working to further progress the project with the help of a £19,000 budget and guidance from a group of four mentors including designer Sabine Marcelis and Yosuke Hayano of Beijing architecture firm MAD.

The studio's plan is to develop a food product from the protein-rich, plastic-eating mealworms, which would then be packaged in the mealworm bioplastic.

The material could be used as a substitute to traditional polystyrene packaging

The material could be used as a substitute to traditional polystyrene packaging

"Mealworm farming has been highlighted in recent years as an environmentally sustainable solution to malnutrition, particularly in developing rural economies," the studio said.

"Growing edible mealworms is affordable, low-resource and space-efficient. The resultant food source is twice as protein-efficient as beef with zero methane emissions."

In this way, the designers say the mealworms could eventually help to tackle two sustainable development goals at the same time, providing food security and fighting pollution.

Chitin can also be turned into a bioplastic film

Chitin can also be turned into a bioplastic film

Early studies have shown that mealworms that have digested polystyrene can still be used to feed other animals, but more research is necessary on whether they could safely be eaten by humans and whether they could be used to break down plastics at a mass scale.

As the mealworms digest the polystyrene, around half of the fossil carbon that was stored in the plastic is also emitted into the atmosphere as CO2, which could contribute to global warming.

The chitin found in their exoskeletons has been much more widely studied and already turned into a range of different materials including a leather alternative and a bioplastic film.

The post Doppelgänger creates polystyrene substitute from plastic-eating mealworms appeared first on Dezeen.

#all #design #materials #products #technology #plastic #insects #packaging #bioplastic #recycling #polystyrene #doppelgänger

Chitofoam can be turned into cups (top image) and packaging materials (above)

Chitofoam can be turned into cups (top image) and packaging materials (above) It can also be formed into packaging peanuts, much like traditional polystyrene

It can also be formed into packaging peanuts, much like traditional polystyrene Mealworms can safely digest polystyrene plastic

Mealworms can safely digest polystyrene plastic Doppelgänger has modelled the packaging on the shape of coral

Doppelgänger has modelled the packaging on the shape of coral

The material has shock-absorbent properties thanks to its foamy texture

The material has shock-absorbent properties thanks to its foamy texture Chitin can also be turned into a bioplastic film

Chitin can also be turned into a bioplastic film

Unwasted bags are made from leftover grapes. Photo is by Osman Tahir

Unwasted bags are made from leftover grapes. Photo is by Osman Tahir The material is a byproduct of the wine industry. Photo is by Osman Tahir

The material is a byproduct of the wine industry. Photo is by Osman Tahir Du shapes the alternative leather over her 3D-printed designs

Du shapes the alternative leather over her 3D-printed designs The bags come in two irregular shapes

The bags come in two irregular shapes

Around 1,200 grapes were used for the Merlot bag

Around 1,200 grapes were used for the Merlot bag The Chardonnay bag is shaped like a tin can

The Chardonnay bag is shaped like a tin can

ACORN's prototype of the concrete vaulted floor is on display at the University of Cambridge

ACORN's prototype of the concrete vaulted floor is on display at the University of Cambridge

The floor prototype used 75 per cent less concrete than an equivalent flat slab

The floor prototype used 75 per cent less concrete than an equivalent flat slab

As a polymer film, 2DPA-1 could give a protective coating to cars, phones or surfaces. Image courtesy of MIT

As a polymer film, 2DPA-1 could give a protective coating to cars, phones or surfaces. Image courtesy of MIT

MCQ has created ten leather jackets using Mirum plant leather

MCQ has created ten leather jackets using Mirum plant leather NFW customised the exact finish of the material for MCQ

NFW customised the exact finish of the material for MCQ Each jacket was hand-painted by Kevin Emerson

Each jacket was hand-painted by Kevin Emerson The rice hulls create a speckled effect in the final material

The rice hulls create a speckled effect in the final material

The illustrations reference nature and gardening

The illustrations reference nature and gardening The material has an off-white colour created using mineral clay

The material has an off-white colour created using mineral clay

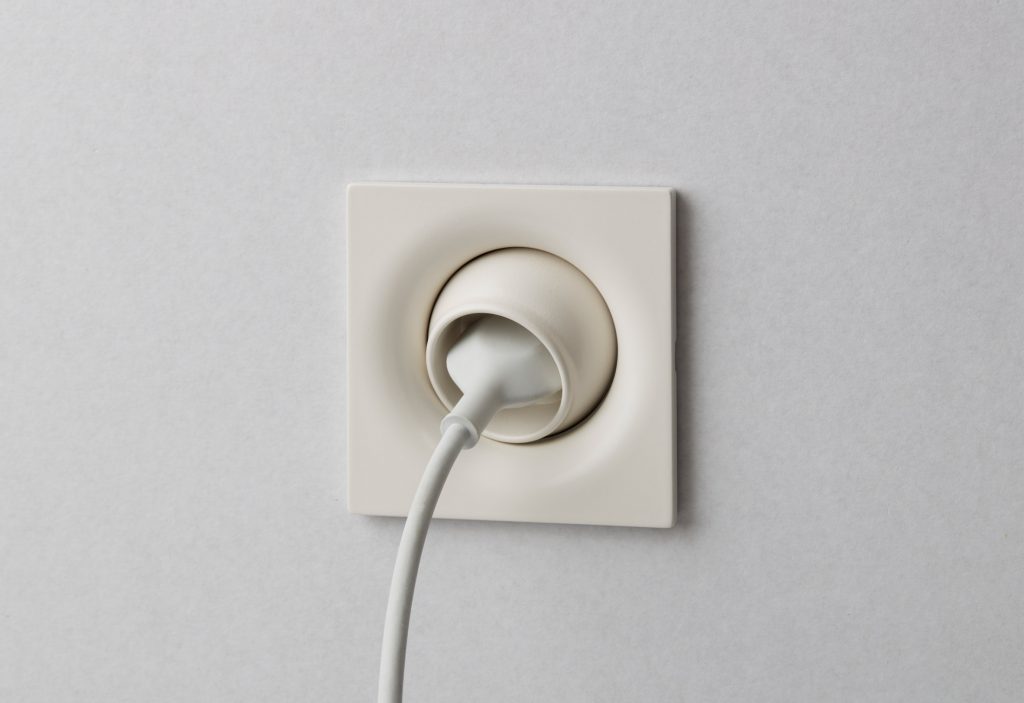

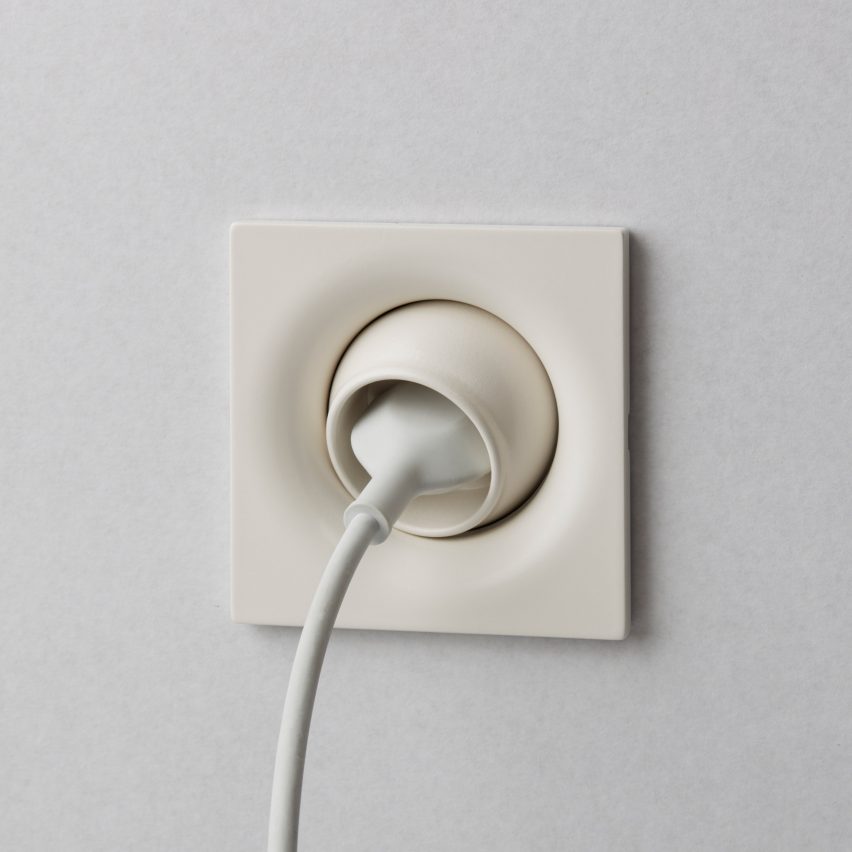

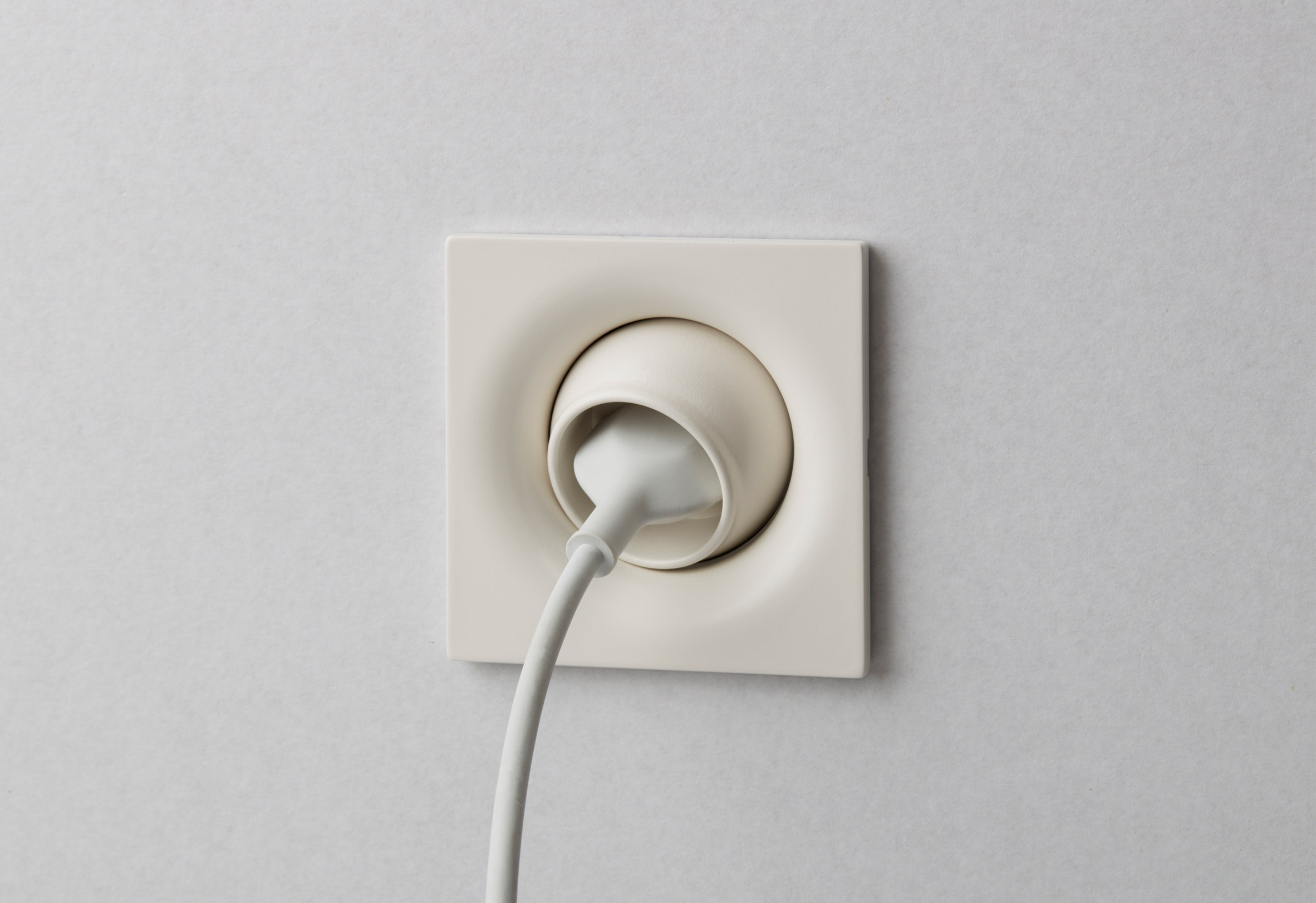

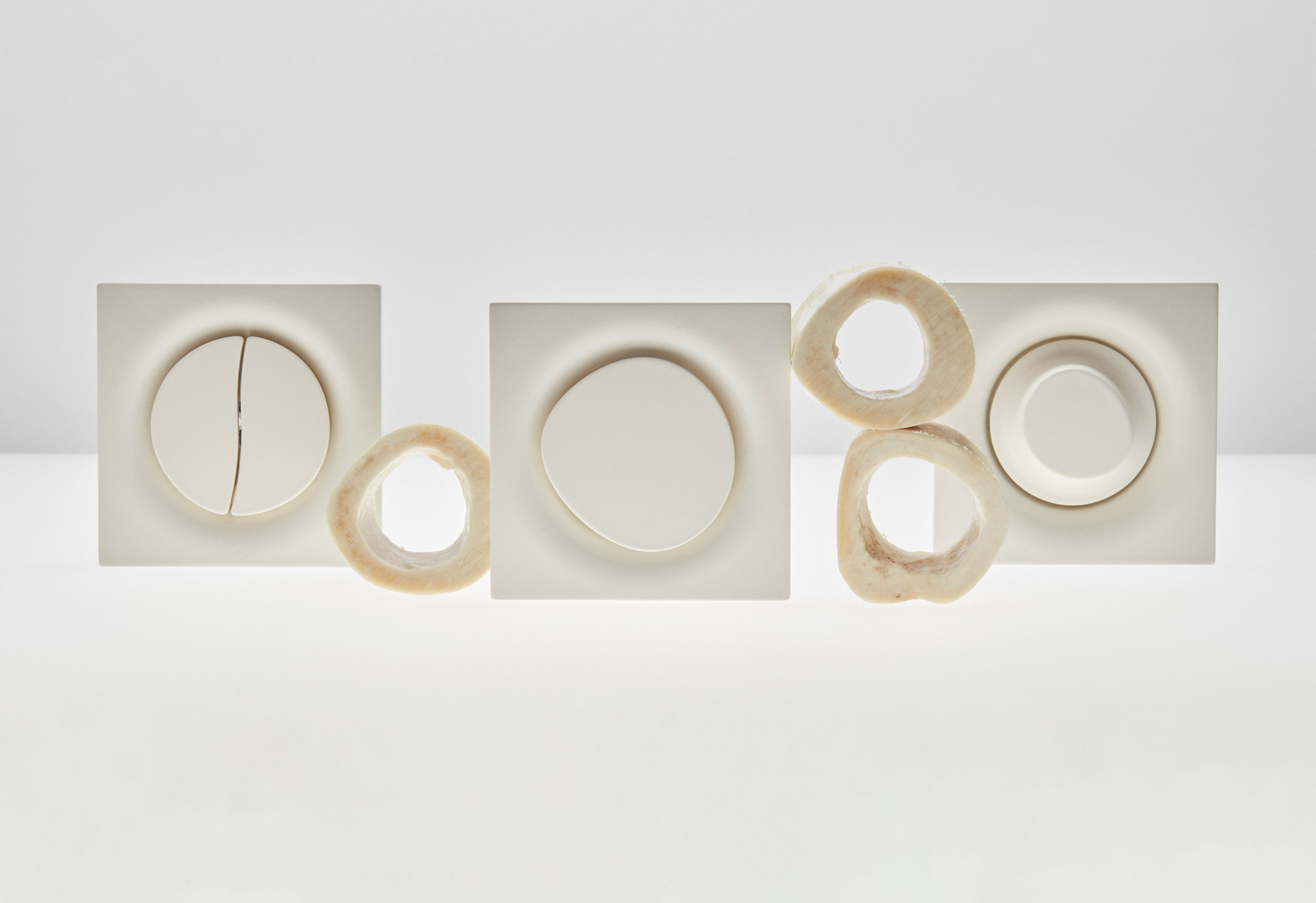

The Elos collection encompasses sockets (above), switches and USB-charging ports (top image)

The Elos collection encompasses sockets (above), switches and USB-charging ports (top image) The fittings are made from bone powder mixed with a bio-based binder

The fittings are made from bone powder mixed with a bio-based binder Phones can rest on the protruding baseplate of the USB port while charging

Phones can rest on the protruding baseplate of the USB port while charging The sockets can rotate to protect cables from wear and tear

The sockets can rotate to protect cables from wear and tear

The light switches are modelled on the shape of a cross-section thigh bone

The light switches are modelled on the shape of a cross-section thigh bone The protruding baseplate can also act as a cable reel

The protruding baseplate can also act as a cable reel