17 Likes

2 Comments

Clouds of various kinds. Evening music.

https://forgeofclouds.bandcamp.com/album/forge-of-clouds

#music_for_evenings #forge_of_clouds #post_metal #poland #pay_what_you_want

#music for evenings #forge of clouds #post metal #pay what you want

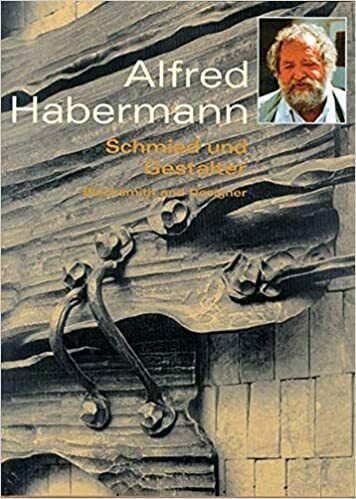

In case any of you is interested in the art of forging, there is this video about Alfred F. Habermann and his skills. He was my teacher in metal and fire. The video was produced by the Bavarian TV company 1993, and luckily Jose Valero uploaded it again.

And, additionally, a video about his wonderful hammers, now produced by Angele.

Both videos are in German only.

#AlfredHabermann #forge #blacksmith #art #artist #video #German #ya

… looking down to the forge through a window in my kitchen. it was from a Swiss villa, I took home after working there. the full brass handles are worth more than the whole thing… those crazies had torn out all windows of that luxurious villa and dumped them in a container; if I had had a bigger car I would have taken them all :D

today had a friend forging damascus steel knives... actually he's a manager and director in a US company in Linz but, his passion is forging... so on and off he comes to improve his skills...

... and since i still have leftovers from the 1 ton of coke in the container, he filled the bucket for me again... funny thing is that in the plain coke there were growing 2 tress, a birch and a willow... had the birch replanted at Andrea's and let the willow do her own thing > she died.

hm... some days ago I forged a crowbar of 92cm/36.2in length.

the original material was a piece of 33cm/13in of that coil spring, probably of an earth mover, the length was still 52cm/20.5in although I had cut off some pieces before... toughest material, I tell ya... took me about 2.5h of sweating :D

I was pissed when my original crowbar of 180cm/70.9in, forged of a loco coil spring weighing 58kg/127.9lb, was stolen last year... I think I know the filcher but, as I was not totally sure I said nothing, instead, forged me this new one, even it is smaller... I need the leveraging effect of a crowbar to move heavier pieces of steel...

Bonjour tout le monde, je suis #nouveauici, mais déjà présent sur Framasphere. Donc je persiste et je signe avec ce bout de Fediverse. Mes centres d'intérêt sont #acab, #anarchie, #arch, #archlinux, #autohébergement, #auto-hébergement, #blacksmilth, #black-smith, #blacksmithing, #black-smithing, #culturelibre, #culture-libre, #darkweb, #death-metal, #debian, #debian-fr, #deepweb, #folkmetal, #forge, #gnu-linux, #hacking, #hacking-social, #heavy-metal, #heroic-fantasy, #kali-linux, #la-quadratre-du-net, #la_quadrature_du_net, #librisme, #linux, #logiciel-libre, #logicielslibre, #melodicblackmetal, #melodic-black-metal, #melodicdeathmetal, #melodic-death-metal, #metal, #motocultor, #mountainbike, #mountain-bike, #mountain-biking, #nouveauici, #nouveau-ici, #nouvelleici, #nouvelle-ici, #opensource, #open-source, #philosophie, #philosophy, #psychanalyse, #psychologie, #psychology, #sciencesdeleducation, #sciences-de-l-education, #sciencessociales, #sciences-sociales, #thrash, #thrashmetal et #thrash-metal.

... another video sent by Jakob in Russia:

How is a forged drill made? Powerful production process of forged steel parts, hammerheads, drills and steel balls, railway components, high strength piles and more ...

Forging is the oldest metal forming process. It originates in the work of blacksmiths many centuries before Christ.

It was manual labor that depended on the strength of the blacksmith's arm. The replacement of the blacksmith's arm occurred in the early stages of the Industrial Revolution.

With the beginning of the industrial revolution, machines were introduced and the blacksmith's arm was replaced by pressure hammers.

Currently there is a varied forging machinery, capable of producing parts of the most varied shapes and sizes, from pins, nails, tools and even giant axes, turbine rotors and airplane wings.

How things are done. Amazing machines.

The content of our videos is for entertainment and the information contained is for you to know what is happening on the screen and has some educational value.

#steel #tools #blacksmith #forge #forging #hammer #drill #production #video

... sharpened some stonemason chisels for Ulrich, and forged a new one (very left) out of special tool steel but, I have to re-forge the third from the right as he wants it pointed 20° and it is 28°...

Ulrich moves between Bugaria and Austria often (approx. 770mi), has bought a house at the Danube in Bulgaria where everything is much much cheaper; e.g. instead of $880 for new brakes he paid only $140 down there. he did not want to tell me his birthday but I know he was born 1949, in Dresden, was imprisoned by the DDR communists and finally fled to West Germany... good guy he is.

Heinz Billen in seiner fahrbaren Schmiede beim historischen Handwerkermarkt in Kempen

#Handwerker #HeinzBillen #Kempen #Niederrhein #Schmied #blacksmith #forge #altesHandwerk #foto #photo #fotografie #photography