Local residents really do not want a #carboncapture pipeline going next to them.

Interesting…in this case I am on the same side as the convoy wacko

https://www.townandcountrytoday.com/beyond-local/out-of-control-crowd-forces-suspension-of-innisfail-council-meeting-9342179

#carboncapture

What they don't tell you about #carbonCapture Heard of Satartia, Mississippi?

https://www.npr.org/2023/05/21/1172679786/carbon-capture-carbon-dioxide-pipeline

Locals to have #carbonCapture #pipeline pass by their homes are not happy #Alberta

https://www.townandcountrytoday.com/beyond-local/some-northern-alberta-residents-dont-like-how-close-carbon-capture-project-pipelines-come-to-their-homes-9232962

One person like that

1 Comments

Quebec eyed as prime spot to suck carbon from atmosphere - Direct air capture is seeing big investment, but big question marks remain

We really need to do this. My only question is how it is paid for, from taxes or is there a way to make it profitable, like making carbon building materials?

5 Likes

9 Comments

Look, someone invented the most efficient carbon capture item in the world!

Don't expect it to be the big news, because it is not a Wall Street scam company behind it and you can't patent it or get money from gullible people or help eco terrorists using it to greenwash their image.

#CarbonCapture #Environment #Farming #OrganicFarming #Planet #Economy #ClimateChange

One person like that

Weltklimakonferenz in Dubai: Positionen und Ausblicke

Weltklimakonferenz in Dubai - Das Ziel ist klar, der Weg wird schwierig

Vor der COP28 gibt es klare Forderungen, wie das 1,5-Grad-Ziel noch einzuhalten wäre. Aber die Ansätze einzelner Staaten unterscheiden sich drastisch.#Umwelt #Klimaschutz #COP28 #CarbonCapture #Energiewende #Emissionen #ErneuerbareEnergien

Weltklimakonferenz in Dubai: Positionen und Ausblicke

One person like that

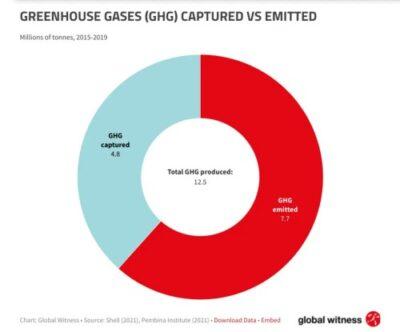

Global Witness Exposes The Lie Behind The Carbon Capture Scam – Shell Claimed 90% Capture But Only 39% Captured In Reality

In 2015, Shell installed a carbon capture facility at its Scotford refinery northeast of Edmonton in Alberta. According to Dezeen, the system was designed to eliminate emissions from hydrogen production. And lo and behold, Shell is trumpeting the fact that it actually captured close to five million tons of carbon dioxide over the course of 5 years. Great news, right?

No, says Global Witness, which claims the facility actually released more carbon emissions than it captured — 7.5 million tons worth, equivalent to the carbon footprint of 1.2 million cars. The greenhouse gases emitted included highly potent methane, which in the short term has a more than 80-times higher global warming potential than carbon dioxide.

Global Witness argues that this casts doubt on the messaging pushed by the oil and gas industry that carbon capture and storage technology makes it possible for hydrogen derived from natural gas to be used as a “low emissions” fuel to help the world reach its net zero goals. “Fossil fuel companies see fossil hydrogen as a way of continuing to make profits from extracting and burning fossil gas, whilst greenwashing it at the same time,” the report says.

See https://cleantechnica.com/2022/01/27/global-witness-exposes-the-lie-behind-the-carbon-capture-scam/

#technology #environment #carboncapture #bluehydrogen #shell

#Blog, ##bluehydrogen, ##carboncapture, ##environment, ##shell, ##technology

5 Likes

4 Likes

2 Comments

Carbon-capturing Celour paint allows anyone to "participate in CO2 removal in their daily lives"

Design graduate Kukbong Kim has developed a paint made from demolished concrete that is capable of absorbing 20 per cent of its weight in carbon.

Called Celour, the paint can sequester 27 grams of CO2 for every 135 grams of paint used.

"That is the same amount of carbon dioxide that a normal tree absorbs per day," Kim said.

The indoor-outdoor paint is made of waste concrete powder, a cement-based residue from concrete recycling that is normally buried in landfills, where it can alkalise the soil and have a detrimental effect on local ecosystems.

Celour is a carbon-capturing paint that comes in three colours

Celour is a carbon-capturing paint that comes in three colours

Through a chemical process called mineral carbonation, which takes place when the paint reacts with the CO2 in the surrounding air, Kim says Celour can reabsorb a significant part of the emissions that were generated by producing the cement in the first place.

Eventually, she hopes to optimise the capturing capacity of the paint so that it completely negates the carbon footprint of the cement it is made from.

"I think it is too early to describe Celour as carbon neutral," Kim said. "It needs further study but I want to make it a carbon-negative product. That is my goal."

"It's not enough if we just stop emissions, as we already have high levels of CO2 in the air," she added. "We need to participate in CO2 removal in our daily lives."

Concrete naturally reabsorbs some of the carbon it emits

Cement is the most carbon-intensive ingredient in concrete and is responsible for eight per cent of global emissions.

But when concrete is recycled, only the aggregate is reused while the cement binder is pulverised to create waste concrete powder and sent to landfill, where it can disturb the pH balance of the surrounding soil.

"Waste concrete powder is high in calcium oxide," Kim explained. "And when it is buried and comes into contact with groundwater or water in the soil, it turns into calcium hydroxide, which is strongly alkaline."

The waste concrete powder is filtered, pulverised and mixed with a binder, water and pigments

The waste concrete powder is filtered, pulverised and mixed with a binder, water and pigments

With her graduate project from the Royal College of Art and Imperial College London, the designer hopes to show the usefulness of this industrial waste material by maximising its natural ability to capture carbon.

Studies have shown that cement already reabsorbs around 43 per cent of the CO2 that is generated in its production through the mineral carbonation process.

This is set off when concrete is cured by adding water, which reacts with the calcium oxide in the cement and the CO2 in the air to form a stable mineral called calcium carbonate or limestone.

A traditional concrete block continues to cure throughout its life but because this process is reliant on exposure to air, only its outer layers will react with the CO2 while its core will remain uncarbonated.

Celour could store carbon for thousands of years

But Kim was able to improve the material's carbon-capturing capabilities by turning the waste concrete pounder into a paint, mixed with a binder, water and pigments.

This is spread thinly on a surface so that more of the material is exposed to the air and can carbonate.

In addition, the coarse powder was further filtered and pulverised to increase the relative surface area of the particles while a polyvinyl alcohol (PVA) binder creates small gaps for air to enter.

"I have done a lot of experiments with different ingredients to maximise carbon absorption by increasing the surface area that comes into contact with carbon dioxide in the air," she explained.

"Graphene, which can capture lots of carbon thanks to its structure, was also considered as a binder but excluded because it is currently priced high and cannot be mass-produced."

The paint can be used both indoors and outdoors

The paint can be used both indoors and outdoors

Cement has long been used to create traditional paint, which is also capable of sequestering CO2. But Kim hopes to harness these carbon-capturing benefits while keeping a polluting waste material out of landfills and avoiding the emissions associated with making new cement.

How long the paint is capable of storing carbon is dependent on what happens to it after it is no longer needed. But Kim says it could be locked away for thousands of years unless exposed to extreme heat, which would alter the chemical structure of the carbonate.

As part of our carbon revolution series, Dezeen has profiled a number of carbon capture and utilisation companies that are working on turning captured CO2 into useful products from bioplastic cladding to protein powder and concrete masonry units.

The post Carbon-capturing Celour paint allows anyone to "participate in CO2 removal in their daily lives" appeared first on Dezeen.

#all #products #design #royalcollegeofart #productdesign #concrete #studentprojects #materials #graduates #paint #cement #carboncapture #carboncaptureandutilisation #mineralcarbonation

1 Shares

Mineral Carbonation International aims "to lock a billion tonnes of CO2 into products by 2040"

Industrial carbon emissions can be captured and turned into useful materials on a vast scale, according to Sophia Hamblin Wang, chief operating officer of Mineral Carbonation International.

"We're trying to embed emissions into as much of our everyday life as possible," said Hamblin Wang. "We turn waste into new products. And we aim to do it in a way that makes money."

The Australian company turns CO2 into raw materials that can be put to a huge range of uses, according to Hamblin Wang.

"We're looking at carpet products, detergents, you name it. Anything that can have carbonates in it can be made from our synthetic carbonates."

Above: Sophia Hamblin Wang is chief operating officer of MCi. Top: the company captures carbon emissions from industries such as steel to turn it into useful materials

Above: Sophia Hamblin Wang is chief operating officer of MCi. Top: the company captures carbon emissions from industries such as steel to turn it into useful materials

Hamblin Wang joined Mineral Carbonation International (MCi) as its first employee in 2013 after the startup received funding to build a pilot plant in Newcastle, New South Wales.

It is now looking to scale up the technology to handle bigger volumes. "Our aim is to lock a billion tonnes of CO2 into usable products by 2040," said Hamblin Wang.

$5.9 trillion construction materials sector "needs to decarbonise"

MCi is initially focussing on producing construction materials, particularly new types of cement and drywall products to replace carbon-emitting Portland cement and gypsum-based materials.

"We know that cement is a heavily emitting industry, like four billion tonnes of CO2 per annum," Hamblin Wang said.

"The industry needs to decarbonise. Our silica products can displace ordinary Portland cement and we're working with giant cement majors on new products."

The construction materials sector is worth $5.9 trillion and, according to Hamblin Wang, there is "an explosion of interest" in low-carbon alternatives.

"Holy moly," she said. "It's been tumultuous in the past two years. We're working with some of the largest companies in the world on charting their path to zero carbon. We're helping them plan the decarbonisation of whole industries and whole facilities."

Slow natural processes can be compressed "into a matter of hours"

The Canberra-based company uses chemical processes that imitate natural weathering to remove carbon from factory emissions and sequester it in solid minerals.

"The earth naturally stores CO2 through a process called weathering, or mineral carbonation," said Hamblin Wang. "It's slower and less glamorous [than other carbon-capture methods] but it's one of the largest ways that the earth currently absorbs CO2."

Carbon dioxide dissolves in rainwater, forming weak carbonic acid. This slowly weathers rock, with the carbon combining with elements released from the rock by the weathering process to form new carbonate minerals.

"This happens over thousands or millions of years," Hamblin Wong explained. "What we've done is we've compressed that process into a matter of hours."

MCi received funding to build its first pilot plant in New South Wales, Australia, in 2013

MCi received funding to build its first pilot plant in New South Wales, Australia, in 2013

Instead of rock, MCi takes industrial waste such as steel slag, mine tailings and bottom ash from incinerators as well as quarried minerals such as serpentinites.

To make its raw materials, MCi bubbles CO2 through the industrial waste, approximating the way water-borne carbon interacts with rock in the natural weathering process. This creates new minerals such as magnesium carbonate, calcium carbonate and silica.

"The minerals absorb the CO2, which effectively gets turned from a gas into a solid," said Hamblin Wang. We then process it into myriad materials and products for everyday life."

MCi buys carbon dioxide from polluting industries

The process is exothermic, meaning the chemical reaction creates heat, so does not involve vast amounts of power.

However, crushing the industrial waste in the first place is energy-intensive. MCi uses renewable energy "where we can," says Hamblin Wang, but future plants will need to switch entirely to renewables if they are to offer a viable contribution to global decarbonisation efforts.

MCi buys its carbon dioxide from polluting industries that have fitted scrubbers to their chimneys to capture the gas before it reaches the atmosphere.

"Right now we take our emissions from an ammonium nitrate factory, which captures its emissions every day," said Hamblin Wang.

"We can carbonate raw flue gas," she said, meaning that MCi is able to purchase emissions containing low percentages of carbon that have few other commercial uses. "We can take it [in concentrations] as low as 15 per cent [CO2]."

Steel industry doesn't have "viable decarbonisation options"

Carbon scrubbing, also known as post-combustion capture, is a long-touted technology that could theoretically remove greenhouse gases from factory flues, preventing them from reaching the atmosphere.

The drawbacks are the cost of retrofitting plants, the fact that it could encourage polluting industries to continue burning fossil fuels, and the issue of efficiency: for a factory to be carbon neutral, one hundred per cent of its greenhouse gas emissions need to be captured.

MCi uses carbon to create building materials such as carbonate bricks

MCi uses carbon to create building materials such as carbonate bricks

However, Hamblin Wang argues that some key industries will struggle to decarbonise due to their high-intensity energy needs, which can currently only be provided by burning and processing fossil fuels.

"The problem is that the steel and cement industries don't currently have viable decarbonisation options," said Hamblin Wang.

"The kind of heat that you need in order to make steel, for instance, you just can't get through electrification. These thermal processes don't have pathways [to net-zero]. You will still need metallurgical coal in order to create steel."

Company aims to make carbon emissions "not only inert but profitable too"

In addition, minerals such as nickel, lithium, cobalt and copper that are vital to making batteries, among other things, all involve carbon-intensive processing.

"There are technologies being developed like hydrogen, but it's still looking like it's 20-plus years in the future," said Hamblin Wang. "If we're looking at a gradient to get to net-zero, those industries are the ones that really need help."

"So our real mission is to help with this transition to capturing the emissions, say, of a steel plant's stack pipe and then rendering those emissions not only inert but profitable too."

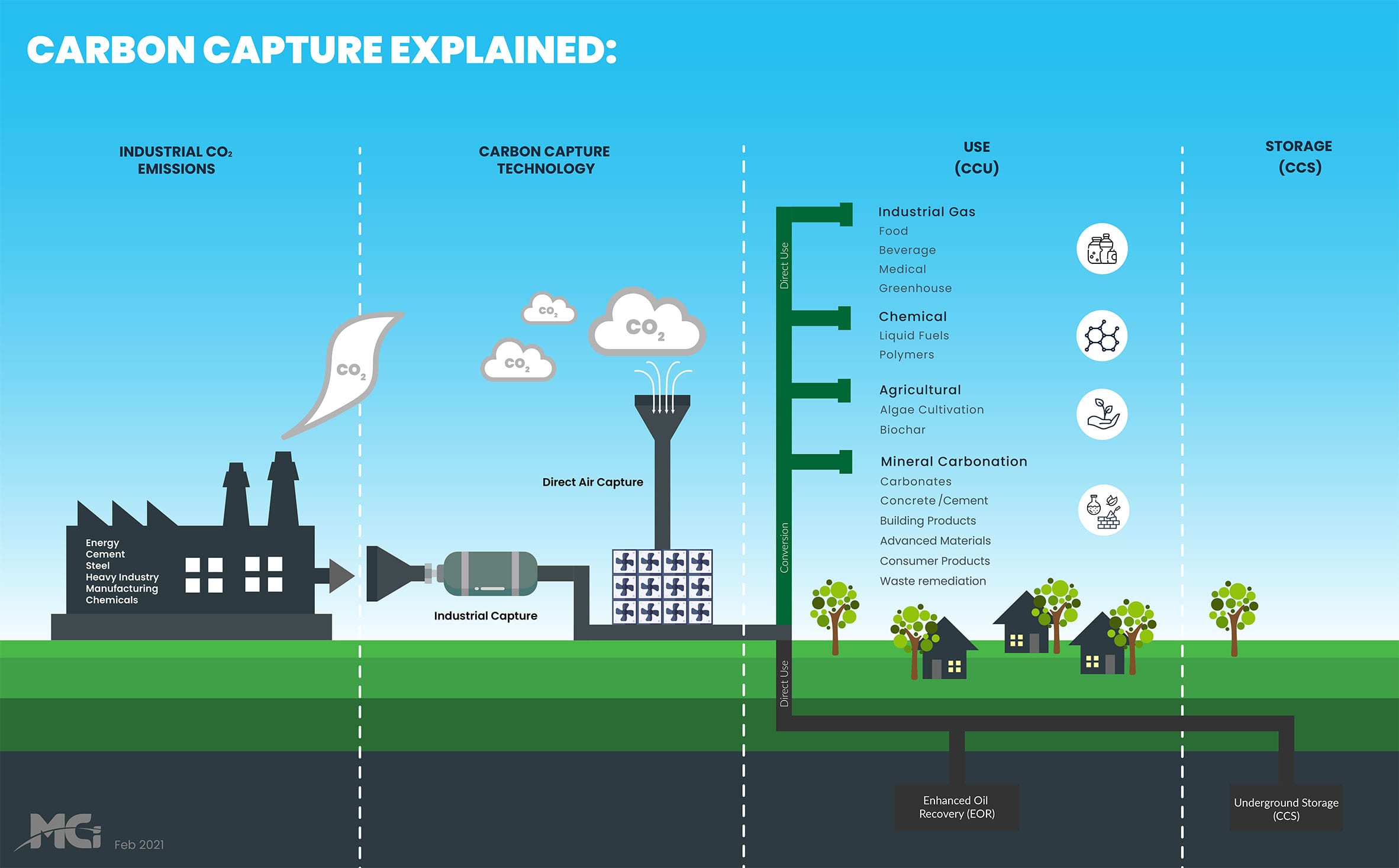

Carbon can be captured and put to use in a range of different ways

Carbon can be captured and put to use in a range of different ways

Hamblin Wang sees mineral carbonisation as one of several emerging approaches that need to scale up and work together to tackle climate change.

These include: dramatically reducing new greenhouse gas emissions; removing anthropogenic CO2 from the atmosphere; and storing or utilising that captured carbon on earth.

MCi is "trying to embrace the circular economy"

Direct air capture technologies such as that developed by Climeworks could one day scale up to significantly reduce atmospheric CO2 but the problem, according to Hamblin Wang, is where to put all the captured carbon.

"Even if we captured all of the CO2 emissions from all of our industry right now, and we suck CO2 out of the atmosphere in the volumes that required, we currently don't have enough places to put the CO2," she said.

Carbon capture and storage (CCS), which involves burying carbon, is "a linear business model where they pump it underground and it costs money and you monitor it forever," said Hamblin Wang.

The alternative is carbon capture and utilisation (CCU), whereby the carbon is put to use.

"We're trying to embrace the circular economy where you turn your waste from your industry and your waste gas into valuable products that can be used in the economy," she said.

"Those products also displace products that would need to be mined or that may have high carbon intensity embedded in them. So the benefit is twofold."

Carbon revolution

This article is part of Dezeen'scarbon revolution series, which explores how this miracle material could be removed from the atmosphere and put to use on earth. Read all the content at: www.dezeen.com/carbon.

The sky photograph used in the carbon revolution graphic is byTaylor van Riper via Unsplash.

The post Mineral Carbonation International aims "to lock a billion tonnes of CO2 into products by 2040" appeared first on Dezeen.

#carbonrevolution #interviews #all #technology #materials #carboncapture

Shopify to spend $5 million per year "to kickstart demand in carbon removal"

Shopify's Sustainability Fund is pumping $5 million into projects that remove atmospheric carbon and publishing the results so other companies can follow its lead, fund director Stacy Kauk told Dezeen.

Established in September last year, the fund "intentionally overpays for carbon removal, funding pilot projects and generating demand to kickstart the market and drive down future prices."

The Canadian e-commerce brand is sharing its research on its website and in a free downloadable 50-page "playbook" document.

Above: Stacy Kauk is director of Shopify's Sustainability Fund. Top: Shopify has created an animation illustrating types of businesses its Sustainability Fund is backing

Above: Stacy Kauk is director of Shopify's Sustainability Fund. Top: Shopify has created an animation illustrating types of businesses its Sustainability Fund is backing

"We wanted to share those commitments so that people can get familiar with the companies and learn about our selection process and the research that we've done," Kauk said.

"It allows folks that don't have an engineer or a scientist on staff doing deep dives into the technical world of carbon removal to know that these are vetted companies. It can give you the confidence to follow along."

Shopify provides services including payment and shipping tools to over 1.7 million online retailers. It is committing money to climate initiatives because it's "on a mission to be a 100-year company," Kauk explained.

"We want to be able to use our $5 million annual climate fund to kickstart demand in carbon removal but to also leverage our platform and use commerce for good."

Shopify has offset its own emissions and is helping its customers offset theirs

Under its climate strategy, the brand has already offset all its emissions going back to 2004 when CEO Tobias Lütke launched Snowdevils, a snowboard e-commerce site that became Shopify in 2006.

"We have offset all our scope 1 and scope 2 emissions, as well as corporate travel, back to 2004," said Kauk, referring to the way greenhouse-gas emissions are categorised by types, or "scopes".

Scope 1 emissions are emissions directly caused by a company, scope 2 covers emissions caused by utilities it buys while scope 3 are indirect emissions caused by the supply chain.

Shopify helps its customers with their own carbon-reduction strategies through its Shop Pay checkout system, which Kauk says is "the first carbon-neutral way to pay".

In addition, Shopify automatically calculates the emissions generated by each shipment, allowing retailers to offset them.

Shopify Sustainability Fund supports companies tackling climate change

The Shopify Sustainability Fund is separate from these initiatives. It is a capital-expenditure project that supports young companies that are developing innovative ways to tackle climate change.

"We have uncoupled our climate fund from our corporate carbon neutral commitments," Kauk explained. "That allows us to spend our $5 million in the most impactful way possible."

In its first year, the fund has funded the removal of sixteen times more carbon from the atmosphere than Shopify itself emits.

"To put it in perspective, our corporate carbon footprint in 2020 was around 6,000 tonnes [of carbon dioxide equivalent]," said Kauk.

"With our first $5 million that we committed through the sustainability fund, we've actually committed to buy well over 100,000 tonnes."

Fund investing in ten industries it believes can reverse climate change

The goal is "to seek out those companies with solutions that we need to spend money on today so that they're there in 5, 10, 15 years," Kauk explained. "When we can no longer reduce our emissions any further, we need these products and solutions to be available to buy."

The fund is putting cash into ten high-potential industries that it believes "can help reverse climate change globally" by permanently capturing and storing carbon.

Almost a quarter of the budget goes to biomass initiatives, supporting companies that turn organic material into renewable energy or carbon-capturing materials including biochar, a high-carbon, charcoal-like substance that increases soil carbon levels as well as being a highly effective fertiliser.

The second biggest spend is on direct air capture, which mechanically removes carbon dioxide from the atmosphere via machines such as those developed by Climeworks.

Next is product, which sees carbon sequestered in useful products such as concrete.

The other areas are soil sequestration, afforestation and transportation, collaboration (including education and sponsorship), renewable energy, mineralisation (storing carbon underground) and ocean sequestration.

Shopify has created a market for high-quality carbon-capture projects

The fund came about in 2019 when Shopify was exploring ways of becoming carbon neutral.

"Our CEO is incredibly passionate about climate and carbon removal and has spent a lot of time learning about this space," Kauk explained. "We have this historical carbon footprint that we wanted to address."

"But we didn't just want to go out and buy a low-cost carbon offset so we could wave our hands and say 'Oh we did it, we're carbon neutral!'"

But after looking for high-quality solutions, the company came to the conclusion that "the product we wanted to buy actually doesn't exist in the market."

So it decided to create the market itself through its sustainability fund.

Companies should not delay committing to carbon removal, Kauk says

Kauk offers advice to companies that are daunted by the complexity of climate change and confused about how to address their own contribution to it.

She suggests a two-track approach: companies should strive to understand their emissions and reduce them as far as possible. But they should not wait until this work is finished before committing money to carbon removal.

"Start that now because it's going to give three benefits," she said.

"One, you're going to get familiar with the market; you're going to learn about carbon removal: what it is, what works and what doesn't. That learning is invaluable."

"The second part is that you're going to have made relationships with these companies who are providing carbon removal as a service," she continued.

"These are gonna pay off down the road because I would hypothesize that we may not have demand matching supply when a lot of these net-zero commitments start to become due."

"And then the third part is that it's going to provide a benefit to that company later on. If a company spends a small percentage of its sustainability budget on carbon removal now, that money is going to help develop these technologies, drive the cost down faster and make these solutions and these high-quality credits more affordable and more accessible sooner."

"This means that in the long run, you'll end up spending less."

Carbon revolution

This article is part of Dezeen'scarbon revolution series, which explores how this miracle material could be removed from the atmosphere and put to use on earth. Read all the content at: www.dezeen.com/carbon.

The sky photograph used in the carbon revolution graphic is byTaylor van Riper via Unsplash.

The post Shopify to spend $5 million per year "to kickstart demand in carbon removal" appeared first on Dezeen.

#carbonrevolution #interviews #all #technology #carboncapture