#austin

● NEWS ● #Techdirt #DRM ☞ #Austin The Latest City To Try And Impose A #Netflix Tax https://www.techdirt.com/articles/20211210/08272948091/austin-latest-city-to-try-impose-netflix-tax.shtml

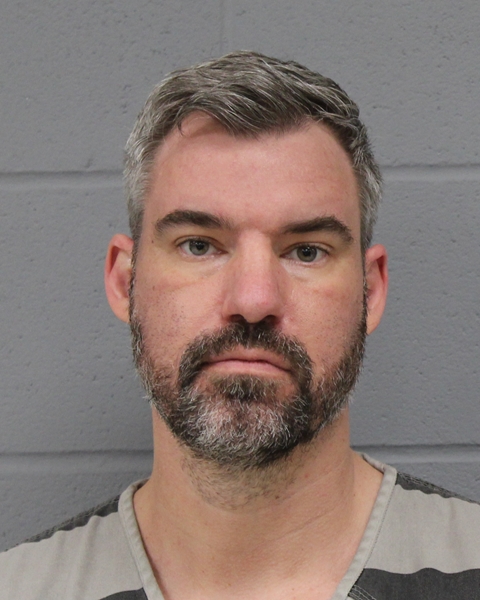

#microsoft #github #crime - The mugshot is now online, accessible through the Web site of the #police department; The #Austin police report itself (there was an arrest) should come up next as we’re redacting the material to protect the victims http://techrights.org/2021/12/14/alex-graveley-mugshot-and-2-links/

How an 11-Foot-Tall 3-D Printer Is Helping to Create a Community

https://www.nytimes.com/2021/09/28/business/3D-printing-homes.html

“We know that being able to #build more #quickly, without sacrificing #quality, is something that we have to make huge leaps on if we’re going to even make a dent on the issue of #housing in our lifetime. The #printer is controlled by a #tablet or #smartphone, requires as few as three #workers and can #complete a #home in #less-than-24-hours."

#11-foot-tall #3-d-printing #creates #community #nacajuca #mexico #village #homes #lavacrete #construction #technology #austin #tx #icon-vulcanll

4 Likes

● NEWS ● #Techdirt #police ☞ #Austin Homeowners Association Pitches In To Help Cops Kill A Guy Over Uncut Grass https://www.techdirt.com/articles/20211030/21510147853/austin-homeowners-association-pitches-to-help-cops-kill-guy-over-uncut-grass.shtml

BIG and ICON to create world's "largest neighbourhood" of 3D-printed homes

![]()

![]()

Construction companies ICON and Lennar are collaborating with architecture studio BIG to create a neighbourhood of 100 3D-printed houses in Austin, Texas.

Scheduled to break ground in 2022, the scheme will be the world's largest community of 3D-printed homes when it completes, according to Texan firm ICON.

![]() The neighbourhood will include 100 3D-printed homes

The neighbourhood will include 100 3D-printed homes

Co-designed with Danish architecture studio BIG, the commuinty is set to be built on an unconfirmed site in the city. More details of the houses' floor plans and design will be announced next year.

Each home will be printed using ICON's Vulcan construction system, which uses controlled robotic machines to create layers of Lavacrete – a propriety Portland Cement-based mix made by the company.

![]() A rendering of construction work at a location in Austin

A rendering of construction work at a location in Austin

"ICON's 3D printing technology produces resilient, energy-efficient homes faster than conventional construction methods with less waste and more design freedom," said ICON.

"Designed and engineered from the ground up for volume 3D-printing of homes with precision and speed, ICON's Vulcan construction system can deliver homes and structures up to 3,000 square feet," it continued.

[

Read:

Seven 3D-printed houses that have been built around the world

](https://www.dezeen.com/2021/05/14/seven-3d-printed-houses-around-world/)

According to the firm, the neighbourhood of houses will be built to the International Building Code (IBC) structural code standard.

ICON also said that it expects its Vulcan-printed homes to last "as long or longer" than those built with concrete masonry units (CMUs).

![]() The houses will be printed using Vulcan technology

The houses will be printed using Vulcan technology

Homebuilding company Lennar will fit each neutrally-coloured house with gabled roofs that will feature photovoltaic panels.

"Our design approach modernises the aesthetic of the suburban home, while the 3D-printing technology texturises and provides distinctive touchpoints for each space," added ICON.

"The freedom of form facilitated by this building technology – including the sinuous curves of the walls – combines with traditional construction materials to create homes that are both aesthetically and physically unique."

The neighbourhood of 3D-printed homes will follow four recently completed houses in East Austin, Texas that were also constructed using Vulcan technology called the East 17th Street Residences.

Other 3D-printed housing projects around the world include an Italian dome-shaped, low-carbon house prototype made from clay and the Netherland's first lived-in 3D-printed home that resembles a grey boulder.

The renderings are courtesy of ICON.

The post BIG and ICON to create world's "largest neighbourhood" of 3D-printed homes appeared first on Dezeen.

#residential #all #architecture #big #usa #3dprinting #texas #austin #americanhouses #3dprintedhouses #icon

● NEWS ● #CommonDreams #texas #tx ☞ 'Needlessly Provocative': #Austin Rebuked for Again Opening #NATO Door to #Ukraine and Georgia https://www.commondreams.org/news/2021/10/18/needlessly-provocative-austin-rebuked-again-opening-nato-door-ukraine-and-georgia

More workers are dying from #heat. #Texas may make it harder to protect them.

source: https://grist.org/health/more-workers-are-dying-from-heat-texas-may-make-it-harder-to-protect-them/

The strikers wanted the city council to require employers to provide drinking water and regular breaks to workers after a survey found that many construction workers were not receiving either, even though temperatures in #Austin have reached as high as 112 degrees F. The campaign was a success — that year, the city council passed an ordinance mandating that construction workers get a 10-minute water break every four hours. In 2015, #Dallas adopted a similar requirement.

But now, E&E News reports that Republican lawmakers in Texas are pushing a #bill that would eliminate these minimal protections that help workers survive on very hot days, which are increasing in number and severity with #climate change.

#work #usa #labour #health #politics #capitalism #humanRights #protection #news

3 Likes

1 Comments

2 Shares

Matt Fajkus adds perforated steel screens to Austin boathouse

Austin studio Matt Fajkus Architecture has designed a boathouse in the Texas city with perforated metal facades calibrated to balance light and shade throughout the year.

Located on the shore of a ravine in Austin, the Filtered Frame Dock is a two-storey boathouse positioned close to a nearby house built above water level.

Filtered Frame Dock sits on the shore of a ravine

Filtered Frame Dock sits on the shore of a ravine

The boathouse has a steel roof arranged in two triangular planes that protect the upper wooden deck from sunlight. The deck is wrapped by glass balustrades and features outdoor lounge chairs.

Filtered Frame Dock gets its name from the perforated stainless steel screens that flank its north and south sides.

Two triangular planes form the boathouse roof

Two triangular planes form the boathouse roof

The screens are designed so that the boathouse receives equal amounts of sunlight and shade during the year, with light and shadow perfectly balanced during the equinox.

"An instrument for light and ventilation, the structure is calibrated to provide a comfortable balance of sun, shade, shelter and breezes throughout the year," said Matt Fajkus Architecture.

The upper deck is wrapped by glass balustrades

The upper deck is wrapped by glass balustrades

"As the seasons shift, the dock provides greater shade during the heat of the summer and welcomes more sun during the cooler winter months."

The laser-cut perforations on each screen are also organised based on sightlines, so that visitors can enjoy views of the water from the deck.

Other materials incorporated into the project are hardwood decking and natural stone, which are intended to echo the boathouse's surroundings.

"Sensory experiences are both articulated by and inherent in the relationship between the dock and its natural context," concluded the architecture firm.

A small balcony juts out above the water

A small balcony juts out above the water

Matt Fajkus Architecture has completed a handful of projects in its home city, including a house with a roofline that mimics a mullet and a mid-century home with an extension formed from wood, stucco and glass.

Boathouses are popular in Austin, since many locals like to enjoy the warm climate by spending time on the water. Architecture studio Andersson-Wise has created two on Lake Austin: one that allows users to dive from its upper level, and another assembled from salvaged materials.

The photography is byLeonid Furmansky, Charles Davis Smith and Matt Fajkus Architecture.

The post Matt Fajkus adds perforated steel screens to Austin boathouse appeared first on Dezeen.

#all #architecture #instagram #usa #perforatedmetalfacades #perforations #texas #boathouses #austin #mattfajkusarchitecture

1 Shares

How do you define yourself? | Lizzie Velasquez | TEDxAustinWomen

https://www.youtube.com/watch?v=QzPbY9ufnQY

#tedx #ted #talk #motivational #speech #lizzie #velasquez #austin #define #yourself #self-worth #self-definition

Logan Architecture and ICON complete "first 3D-printed homes for sale in the US"

![]()

![]()

A quartet of houses designed by local firm Logan Architecture and built from 3D-printed concrete by construction tech company ICON has completed in Austin, Texas.

The East 17th Street Residences in East Austin are now on the market, which construction company ICON and developer 3strands claim is a first. "They are the first 3D-printed homes for sale in the US and ready for move-in," ICON told Dezeen.

![]() The East 17th Street Residences development includes four homes of varying sizes and layouts

The East 17th Street Residences development includes four homes of varying sizes and layouts

The four dwellings have ground-floor walls built using ICON's Vulcan construction system, which uses a robotic armature to layer Portland-cement-based material Lavacrete into striated surfaces.

ICON claims that this process creates a stronger and longer-lasting building material compared to traditional techniques, and makes the homes tougher in the face of extreme weather.

![]() Each of the houses has a ground floor built using an additive manufacturing technique

Each of the houses has a ground floor built using an additive manufacturing technique

"3D-printing technology provides safer, more resilient homes that are designed to withstand fire, flood, wind and other natural disasters better than conventionally built homes," said the company.

The 3D-printed elements for the development, which comprises two two-bedroom homes and two four-bedroom homes, were completed in March 2021. It took five to seven days to print each house.

![]() Black standing-seam metal clads the timber-framed upper floors

Black standing-seam metal clads the timber-framed upper floors

Although differing in size and layout, all four of the 3D-printed homes have the same external and internal features.

Black standing-seam metal clads the timber-framed upper floors and roofs, while large porches have red cedar undersides.

The houses' interiors were designed by Austin-based Claire Zinnecker, who referenced southwestern design when creating the spaces.

"Drawing inspiration from the homes' natural structural materials, wood, metal and concrete, she chose a simplified colour palette of green, white and terracotta and fixtures that play off the natural materials," ICON said.

![]() Minimal interiors by Claire Zinnecker draw influences from southwestern design

Minimal interiors by Claire Zinnecker draw influences from southwestern design

The open-plan spaces have a neutral palette, with wood cabinetry, woven rugs and touches of greenery.

Zinnecker also incorporated glazed saltillo tiles from her collection for local company Clay Imports into some of the homes.

![]() Kitchens feature wooden cabinetry and marble countertops

Kitchens feature wooden cabinetry and marble countertops

Flooring downstairs is finished with a concrete overlay, while engineered wood is used upstairs. Double glazing, tankless water heaters and variable capacity AC systems are all included to help with energy efficiency.

Of the small development, the two-bedroom properties are currently under contract, but both of the four-bedroom houses are still available.

![]() The striations created by the printing process are visible on the interior walls

The striations created by the printing process are visible on the interior walls

3D-printed homes are popping up all over the world, built using a variety of materials that range from bioplastic to clay, and even waste from rice production.

ICON's 3D-printing technology is also being used to build a prototype habitat for Mars, designed by architecture firm BIG in collaboration with NASA.

The company is also working with the space agency on robotic construction techniques for the Moon, and planned a community of affordable printed houses in Latin America with Fuseproject.

Photography is byRegan Morton Photography.

The post Logan Architecture and ICON complete "first 3D-printed homes for sale in the US" appeared first on Dezeen.

#residential #all #architecture #news #usa #houses #3dprinting #texas #austin #americanhouses #3dprintedhouses #icon

Lake Travis, Austin, Texas. From Mansfield Dam. 2018. #Photography #Photograph #UrbanPhotography #Lake #Austin